Mushroom Matter

Welcome on our platform. Why MUSHROOM MATTER? Because mushrooms play an important role in our lives as well in business. Our goal is to bring the world the very latest mushroom news with the upmost care to support the positioning of our beloved Mushroom.

Fungi have revolutionised medicine, yielding some of the most crucial pharmaceuticals in history. From the accidental discovery of penicillin in 1928 to the blockbuster statins that transformed cholesterol management, fungal-derived compounds have shaped modern healthcare. But as researchers exhaust conventional screening methods, new genomic tools and bioinformatics are opening up fresh opportunities for drug discovery.

A fascinating review from London Kew Gardens's research team published in Biomolecules (Prescott et al., 2023) delves into the past, present, and future of fungal drug discovery, highlighting approved drugs, clinical trials, and innovative approaches that could unlock the next generation of therapeutics.

A History of Game-Changing Fungal Drugs

Fungi have provided key treatments for chronic infections, autoimmune diseases, and metabolic disorders. Penicillin, derived from Penicillium rubens, was the first antibiotic and remains one of the most important medical discoveries of the 20th century. It paved the way for cephalosporins, another major class of antibiotics originally extracted from Acremonium chrysogenum. These compounds revolutionised medicine, drastically reducing mortality from bacterial infections.

Antifungal drugs have also emerged from fungal sources. Penicillium griseofulvum produces griseofulvin, used to treat dermatophytic infections, while Aspergillus spinulosporus is responsible for echinocandins, a crucial class of antifungals that inhibit fungal cell wall synthesis and are often used for severe, resistant infections.

Please read the full article here.

Source: MycoStories

Photo: Marc Violo, founder at MycoStories

Strategic partnership

GTL Europe B.V. would like to inform you about an exciting development at their company.

"We are pleased to announce that Hoving Group and GTL Europe B.V. have entered into a strategic partnership. This collaboration will enable us to further improve and expand our services and products and enhance our service provision to our customers".

What does this mean for you?

• Efficient execution of complex projects: The mushroom industry is experiencing strong global consolidation, resulting in increasingly large and complex projects. Joining forces will enable us to continue to execute these projects efficiently and professionally.

• High quality and efficiency: Both companies manufacture some of the same machines at an equivalently high and professional quality level. By combining our expertise, we can implement new developments more quickly and efficiently.

• Optimised focus: Thanks to this collaboration, Hoving will increase its focus on phase 1-2-3 machines, while GTL will concentrate on harvest optimisation in response to market demands.

• Innovative solutions: There is a high demand from the market for solutions to optimise and automate harvesting, and AI technology will also be implemented in our sector.

• Stronger service: Through our partnership, we can provide enhanced 24-hour service.

We are confident that this collaboration will have a positive impact on your experience with our company. If you have any questions or would like more information, please do not hesitate to contact us.

Thank you for your continued trust and we look forward to serving you even better.

Best regards,

Johan Hoving

CEO

Hoving Group

Jack Lemmen

CEO

GTL Europe B.V.

When it comes to sustainable eating, mushrooms are the ultimate MVP. Not only do they add savory umami flavor and rich meaty texture to your favorite dishes but their growing process has a remarkably low environmental footprint. In fact, according to a study by SureHarvest, mushrooms are considered “one of the most sustainably produced foods in the U.S.,”1 making them a perfect ingredient to celebrate Earth Month.

Small Footprint, Big Impact

Mushrooms are grown using minimal resources, so growers are able to produce millions of pounds of mushrooms on just a few acres of land.1 Soil used to produce mushrooms is made of pasteurized composted materials transforming what would be waste into nutrient-rich food. Producing one pound of mushrooms:

- Requires only 1.8 gallons of water1

- Generates only 0.7 lbs of CO2 equivalents1

- Requires only 1.0 KWH of electricity1

Once mushrooms are harvested, this soil can be repurposed in multiple ways. One way it is used is as potting soil, enriching it with beneficial nutrients and organic matter to support enhanced plant growth. This full-circle approach minimizes waste, enhances soil health and contributes to a more sustainable food system.

Healthy on the Plate, Gentle on the Planet

Mushrooms aren’t just good for the earth, they’re a superfood source of nutrients, too. A rich umami flavor and meaty texture make them a perfect plant-based pairing with vegetables, grains and proteins.

You can read this interesting article further on Mushroom Concil

Coating of cultivation cells at Geurts Champignons

Testimonial RibbStyle – Geurts

Our RibbStyle coating solutions protect and improve the sustainability of mushroom farms. At Geurts Champignons, we applied our high-quality coatings to protect the cultivation cells, walls and ceilings against the effects of moisture and rust. With Ribbstyle's expertise, farms can continue their production process optimally, without compromising on quality and hygiene.

The assignment

We visited the mushroom farm of family business Geurts at the right time: the cultivation cells needed to be recoated. We treated the doors of the cultivation cells against rust, as the humid climate had already caused the doors to be severely damaged. We stopped the rusting process with our Metalcoat. We had to treat the doors in parts, so that production could continue. This was a challenge for us, but we are known for our flexibility and ability to adapt.

In the new packing hall, we treated the wall of cellular concrete. We sealed the seams with Ribbseal, sprayed the wall with our Indoorcoat and applied a topcoat from HG in the desired colour. The result is a wall that is easy to clean and does not attract dirt.

Geurts about RibbStyle

We are very satisfied with the quality of RibbStyle. They always keep their agreements, which is not self-evident in this day and age. They are highly visible on the market and deliver professional work. In addition, they understand the mushroom sector and the strict certifications that go with it. Another big plus is the pleasant collaboration with Tamara.

Source article and photo: Mushroom Matter

GROWTIME has just introduced new features in its NEWTON (and PASCAL on 2015) lorries that make daily work easier and increase yields. With RFID and iButton technology, lorry settings are now effortlessly managed—and fully controlled by the team leader.

Optimized driving speed, access authorization, and enhanced safety are just the beginning. Discover how a simple tap of a card or chip can transform your picking process. Want to get the most out of every square meter?

Find out how the new features in NEWTON and PASCAL lorries can increase your yield by up to 2.5 kg/m².

Read the full article here and see how smart technology is working for your success.

Source article and photo: GROWTIME

See how GROWTIME transforms mushroom harvesting!

For over five years, Damian Marciniak has been working with GrowTime, and the results speak for themselves! Thanks to innovative mushroom picking lorries, the company has significantly improved working conditions and increased efficiency. Employees experience less physical strain, and the harvesting process has become more effective.

Damian Marciniak praises the reliability of the equipment, as well as the excellent communication and fast order fulfillment. Want to see how modern solutions impact daily work? Watch the full video and see for yourself!

Watch the video here.

Edible mushrooms could be used as a natural intervention to regulate blood sugar and improve metabolic health, a new study from Semmelweis University suggests. With global rates of type 2 diabetes (T2DM) on the rise, the researchers shed light on how bioactive compounds in medicinal mushrooms, such as polysaccharides and terpenoids, may help prevent or alleviate insulin resistance (IR).

Common mushrooms like white button (Agaricus bisporus), shiitake (Lentinula edodes), and oyster (Pleurotus ostreatus), now widely consumed as part of the Western diet, could serve as preventative or complementary treatments for managing insulin resistance, according to a comprehensive review recently published in the International Journal of Molecular Sciences.

IR occurs when the body’s cells fail to respond properly to insulin, causing glucose to build up in the bloodstream. Over time, this can lead to T2DM, a condition that affects an estimated 830 million people worldwide, as data from the World Health Organization shows.

The bioactive components in mushrooms include polysaccharides, terpenoids, phenolic compounds, and bioactive proteins, along with essential vitamins and minerals. These compounds interact with key metabolic processes to promote better insulin sensitivity and overall metabolic health.

For example, indigestible polysaccharides, a major fibre component of mushrooms, contribute to metabolic balance by feeding beneficial gut bacteria. These bacteria support nutrient absorption, strengthen the intestinal barrier, and lower chronic inflammation - an important factor in insulin resistance. Additionally, polysaccharides reduce sugar and fat absorption, which aids in weight management, crucial for both preventing and managing diabetes.

"Recent research has highlighted the significant impact of gut health on conditions like obesity and type 2 diabetes," explains Dr Zsuzsanna Németh, a biologist at Semmelweis University’s Department of Internal Medicine and Oncology and the study's lead author. "By nurturing gut bacteria through diet, we can improve insulin sensitivity and overall metabolic health."

Other ways of how bioactive components in mushrooms could improve IR:

- Modulating glucose absorption: Mushroom compounds regulate intestinal enzymes, slowing the rate at which glucose enters the bloodstream, thereby preventing sharp blood sugar spikes.

- Enhancing glucose uptake: By improving insulin signaling pathways, bioactive components help transport glucose more efficiently into muscle and fat cells.

- Balancing insulin production: Mushrooms can stimulate insulin secretion by pancreatic β-cells and protect them from cell death by increasing the expression of the GLP-1 hormone, helping to maintain healthy blood sugar levels.

- Optimising lipid metabolism: By promoting the use of free fatty acids as an energy source, mushrooms reduce harmful fat accumulation and support healthier muscle function.

- Improving adipose tissue function: Pathologically enlarged fat tissue produces pro-inflammatory substances, contributing to insulin resistance. Medicinal mushrooms may help restore optimal fat storage and release while promoting the production of anti-inflammatory adiponectin, thereby improving metabolic balance.

- “Our study reveals the remarkable potential of natural compounds in mushrooms to address key metabolic pathways," adds Dr Németh. "As interest grows in non-pharmacological approaches to disease prevention, this opens up exciting possibilities for using edible medicinal mushrooms as complementary agents in diabetes management."

However, Dr. Németh advises that in cases of illness, supplemental mushrooms should be consumed as part of a balanced diet and under the guidance of healthcare professionals.

Please read the full article here

For press enquiries and interviews please email our press office: This email address is being protected from spambots. You need JavaScript enabled to view it.

Fungal Diseases

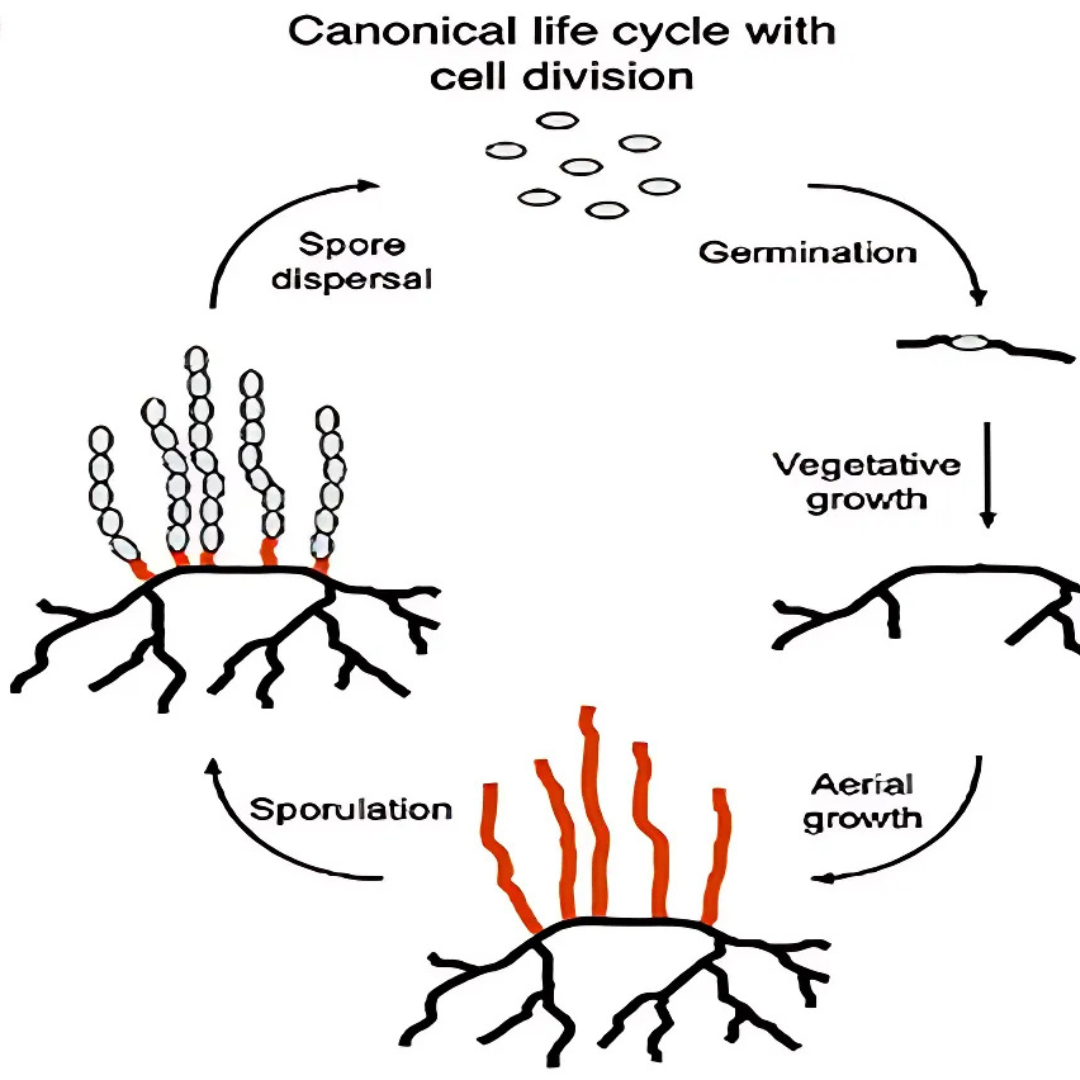

The life cycle for fungal pathogens like Dry Bubble, Trichoderma, and Cobweb is simple, Figure 1. Spores germinate into mycelium, which forms structures that produce spores. In a petri dish culture that may take less than a week; in compost or casing, it is probably pretty much the same. However, other factors like pH, moisture, and nutrient availability may influence this life cycle timing. Much of that, however, is unknown for these pathogens.

| Figure 1 Typical fungal life cycle showing spores to fruiting. Source: researchgate.net |

Looking at the disease cycle in mushroom cultivation, we know a relationship exists between spore load, time of infection, and symptoms or signs of disease development. Let’s look at the three most common fungal diseases and what we know about these relationships.

Dry Bubble, caused by Lecanicillium, or Verticillium has symptoms that develop based on spore load and timing of infection. Spores coming in contact with a fully colonized spawn run don’t germinate well and little disease will develop. It may be possible that spores landing on the substrate the day before or the day of casing could cause an early disease development. Spores in contact with the rhizomorphs in the casing will easily germinate. How fast they germinate, and the vegetative mycelium growth may be influenced by casing pH, moisture, relative humidity, and temperature.

It is unknown what the optimum conditions are but in general the warmer the conditions the faster the growth and the shorter time from spore to symptom development. In general, spore to symptom takes about seven to 14 days depending on the above factors. However, when Dry Bubble mycelium is in contact with mushroom pins,metabolites are produced that degrade mushroom tissue. This process seems quick, perhaps hours to a day or two.

Read the full factsheet here.

Written by: David M. Beyer