Picking and calibration

Generally picking is considered by many as a low education job. But on the other hand, we rely on our picking force to deliver a good quality mushroom, meeting the customer demands. No bruised mushrooms, no nail or knife damage, right stem length, straight cut stem, no weak mushrooms in the punnet and for all, the right size. And that is where many things go wrong. It is fairly easy to learn the pickers the right way of picking. Twist and do not pull. Do not take to many mushrooms in one hand so they do not get damaged and put them caps up into the punnet. But getting the calibration right is a constant struggle. Pickers tend to have the habit to pick too small and this will cost you money. They simply pick the mushrooms that were meant to be picked tomorrow. An extra thing to that is that pickers lose the bonus while working really hard.

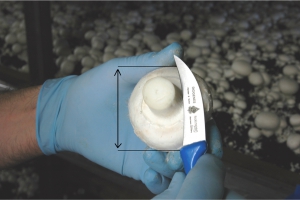

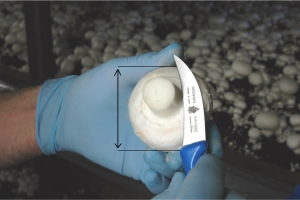

For the right calibration there are many tools like fruit grading rings, grading cards and other different tools. But the easiest tool they have in their hands: the knife.

The knife most used in mushroom growing is the curved knife and the length of the blade is exactly 60 mm. The calibration most wanted on many farms is 55 to 60 mm. Generally, this size is picked first before thinning out. And this is just the size of mushroom that is as wide as the length of their knife. They just have to keep the knife just above the mushrooms to judge the size. This way the mushrooms can be calibrated before they are picked and they will not be damaged by any other form of grading tools. The rings only let mushrooms through which are small enough. The bigger mushrooms get stuck and will be damaged. But the mushrooms that go through easily are too small and that is the calibration the picker will harvest. By using the knife not only there will be no damage but it is also faster.

If a smaller calibration is harvested like a 40 mm mushroom, a line can be made on the blade with a marking pen. Especially new pickers will be very fast in learning this trick. By banning the calibration rings also, the hygiene on the farm is served. Because these rings are hard to clean and experience learns that they are always dirty and are taken from room to room.

Give it a try and your harvesting staff will be happy.

Mushroom picking - ergonomics and profitability

More than 13 years of discussions with mushroom growing farm owners around the world convinced us to make one statement: one of the main factors generating significant costs for mushroom growing farms is workers' wages, and they work most efficiently (they pick faster and more with relatively less fatigue) when optimal working conditions are created for them.

It is no secret that the worker who picks mushrooms spends most of the day on the platform of a mushroom picking trolley, and its proper construction is the key to facilitating the daily work.

Below are some of the factors that determine, in large part, whether after a day of hard work your employees are still productive and will easily return to work the next day or whether they feel physically exhausted and their productivity is simply low.

- The ease of reaching the mushrooms through a smooth, automatic movement up, down, right and left - the essence of the work of the person who picks the mushrooms is to reach the mushrooms which have grown to the right dimensions quickly and easily. The difference between manual, semi-automatic and automatic solutions is crucial: time and difficulty in moving. Automatic solutions (trolleys with a suitable platform) allow to reach the mushrooms more easily while saving energy of the picker.

- Appropriate adjustment (height, inclination, distance) of the shelves for mushroom containers. In addition to reaching the right mushroom, it needs to be picked and then put in a container. Shelves for packaging / boxes should be properly adapted to the figure and range of motion of the person picking the mushrooms. Facilitating this activity means faster and less tiring picking, and we are talking about an activity that is repeated every day even thousands of times!

- Seat adjustment. The height of the "seat" and the distance from the box/package shelves should be adjustable in order to be able to adjust it to the distance from the mushroom containers, but also above all to the height of the person who picks the mushrooms. Comfortable body placement means less fatigue and less fatigue means faster and more efficient work.

- Perfect shape and thickness of profiles. Most mushroom carts have rails that not only protect against falling out, but above all should have a geometry that also facilitates the motion / movement of a person on the platform, facilitating movement on the platform, supporting the employee who repeatedly holds onto them while standing up or sitting down. Rails should be of adequate strength and preferably rounded, ergonomic shape to ensure safety and enable a solid hand grip.

- Location of the pilot and brake. A modern picking trolley is controlled by an intuitive remote control, which should be placed in such a place that it is easy to access (without straining the body, without unnecessary movements) and allows controlling it with both hands.

- Trolley components which are subject to maintenance and assembly/disassembly. Part of the daily work of the mushroom picker is also the preparation of the trolley for work by assembly or disassembly of the drive and washing and disinfection of the elements of the trolley. Good mushroom picking trolleys are designed for these activities to be performed quickly, easily (without requiring specialized personnel) and without undue impact on the wear of the trolley components.

- Easy, possible picking from the bottom shelf of the shelving. Non-customized solutions (choosing the wrong design of the trolley) may result in the necessity of additionally strenuous, physical work on the picking of the mushrooms from the bottom shelf of the shelving or prevent any picking at all, because the floor of the trolley platform is located too high to be able to easily reach this shelf from the platform. It is worth choosing such trolleys that will enable ergonomic picking from all shelves of the shelving, including the last one.

The key to optimizing the efficiency of harvesting in a mushroom growing farm is the choice of such devices that will actually speed up and facilitate the work of employees, because in the vast majority of mushroom growing farms around the world, it is the human resources that constitute one of the largest fixed costs of the mushroom growing farm's operation.

It is a common mistake to choose the cheapest trolleys, not the ones that are best thought out in terms of construction and enable the most ergonomic, and therefore efficient, work for our employees. By choosing a better, and therefore usually more expensive, solution, we can save a lot, because the process of mushroom picking will ultimately turn out to be much cheaper using the potential of the right devices.

—

The article’s author is GROWTIME (growtime.eu), a manufacturer of high-end mushroom picking trolleys used by leading mushroom growing farms around the world. If you are interested in mushroom picking trolleys, then check out our leading products:

● Mushroom picking trolley PASCAL - https://growtime.eu/en/produkt/pascal-picking-trolley/

● Mushroom picking trolley NEWTON - https://growtime.eu/en/produkt/newton-picking-lorry/

Picking and calibration

Generally picking is considered by many as a low education job. But on the other hand, we rely on our picking force to deliver a good quality mushroom, meeting the customer demands. No bruised mushrooms, no nail or knife damage, right stem length, straight cut stem, no weak mushrooms in the punnet and for all, the right size. And that is where many things go wrong. It is fairly easy to learn the pickers the right way of picking. Twist and do not pull. Do not take to many mushrooms in one hand so they do not get damaged and put them caps up into the punnet. But getting the calibration right is a constant struggle. Pickers tend to have the habit to pick too small and this will cost you money. They simply pick the mushrooms that were meant to be picked tomorrow. An extra thing to that is that pickers lose the bonus while working really hard.

For the right calibration there are many tools like fruit grading rings, grading cards and other different tools. But the easiest tool they have in their hands: the knife.

The knife most used in mushroom growing is the curved knife and the length of the blade is exactly 60 mm. The calibration most wanted on many farms is 55 to 60 mm. Generally, this size is picked first before thinning out. And this is just the size of mushroom that is as wide as the length of their knife. They just have to keep the knife just above the mushrooms to judge the size. This way the mushrooms can be calibrated before they are picked and they will not be damaged by any other form of grading tools. The rings only let mushrooms through which are small enough. The bigger mushrooms get stuck and will be damaged. But the mushrooms that go through easily are too small and that is the calibration the picker will harvest. By using the knife not only there will be no damage but it is also faster.

If a smaller calibration is harvested like a 40 mm mushroom, a line can be made on the blade with a marking pen. Especially new pickers will be very fast in learning this trick. By banning the calibration rings also, the hygiene on the farm is served. Because these rings are hard to clean and experience learns that they are always dirty and are taken from room to room.

Give it a try and your harvesting staff will be happy.

Dry mushrooms with fresh air

A lot of farms are afraid that water directly on mushrooms will damage the quality but I disagree with that. Of course it depends on the amounts of water you use and the moment of watering, those details are very important but if managed well the water on the mushrooms will give them a smooth cap and some extra weight. What we need to keep in mind is that the moment of watering is very important. Wait for watering on the 1st flush until you see compost activity. If there is no rise in compost temperature wait with water until there is. Normally you see the activity starting on the first picking day when you pick about 0.5 to 1 kg/m2. I always like to water on that first picking day, where the compost just starts to get activity, and let the mushrooms dry naturally, with no force of the fan but with fresh air. What happens is that when you run higher fan speeds after the watering, the fresh air damper will close. You can put a drying program where you lower the CO2 a bit but still the higher fan speed will not increase the amount of fresh air that is needed to dry the mushrooms.

Instead dry the mushrooms naturally and without too much help from the fan speed. Speeding up the fan a lot is not sufficient and is actually working the other way around. When the room is watered the RH is high so the climate system will automatically start drying the room. Leave the fan speed the same so some extra fresh air will come in to do the drying process. Make sure to remove all the access water from the floor directly after watering, if not the process will dry the floor first and the mushrooms will stay wet longer. Make sure you watch your outside conditions to guide this process, with very high humilities you have to use a drying program or consider not too water.

Filling and picking organisation.

If you look at this in a glance one might say: the filling has not that much to do with picking. But it is more relevant than many people think. Before the start of picking a first flush, the picking manager makes a plan. When is the room starting? Do I have to pick clusters or pre-runners? How many pickers do I need in this room during lets say 5 days of picking? And an important one, what is the activity of the room? This I need to interact on the growing from day 2 of picking. And this is where the filling of the room comes into the story.

Before the start of picking the picking manager and the grower have a talk about this room. This should start from the moment pins grow out, so about 4 days before the start of picking that room. The picking manager has knowledge about the expected sales that week, the desired size of the mushrooms and the number of pickers available. The grower has knowledge of the room regarding the activity of the compost, the strain and the number of pins developing. An even room is easy to evaluate but if the filling was uneven or two different types of compost were used, than the story gets a bit more difficult. The growing room will develop uneven and one side might start earlier. One side might give more mushrooms and this means that the picking is not the same on all shelves. And with the tendency to build bigger rooms, more trucks of compost are filled in a room. And every truckload of compost can be a bit different. Sometimes in structure, sometimes in moisture content and even in quantity. And every time the operator of the combine filling machine has the desire to change the settings on the machine. Often his order is to get the compost filled. All shelves full and no compost returning to the compost yard or no compost dumped. But by changing the settings the temperature development of the compost will change too. 2 cm deeper fill can result in a difference of a day for the flush to start. It will also have an effect on the number of mushrooms growing out. And during the flush one side will grow faster than the other.

So the general instruction at filling should be not to make any changes. Better a bit of compost left over or a part of the shelves not being filled. An even better way is to fill out of two trucks in one go with a cross conveyor. That way the compost out of two trucks is mixed and differences are ruled out. Another method is to do a mixed fill of the truck at the compost yard. So fill a layer, fill another layer in another truck and then let the trucks circulate. Of course the best possible way is to do the mixed filling of the truck, together with the combined unloading at filling. The growing will be a lot easier then. The grower has a better chance to produce the number of mushrooms required and the picking can be a lot more accurate.

Researchers in Penn State’s College of Agricultural Sciences have developed a robotic mechanism for mushroom picking and trimming and demonstrated its effectiveness for the automated harvesting of button mushrooms.

In a new study, the prototype, which is designed to be integrated with a machine vision system, showed that it is capable of both picking and trimming mushrooms growing in a shelf system.

The research is consequential, according to lead author Professor Long He, because the mushroom industry has been facing labour shortages and rising labour costs. Mechanical or robotic picking can help alleviate those problems.

Please read the full article here.

Source: E&T Engineering and Technology