Mushroom Matter

Welcome on our platform. Why MUSHROOM MATTER? Because mushrooms play an important role in our lives as well in business. Our goal is to bring the world the very latest mushroom news with the upmost care to support the positioning of our beloved Mushroom.

What’s moving the mushroom industry right now?

The mushroom sector continues to evolve at pace. Automation, labour availability and cost efficiency remain dominant themes, while growers balance innovation with reliability on the farm floor.

Below are a few developments worth watching.

1. Automation: progress, but not autonomy

Robotics in mushroom harvesting keep improving, yet fully autonomous solutions are still limited in peak and variable flush conditions. As a result, more growers are exploring hybrid harvesting models, where technology supports – rather than replaces – skilled labour. The focus is shifting from “full automation” to consistency, ergonomics and uptime.

2. Labour strategy is becoming a technical issue

Labour shortages are no longer just an HR concern. Growers are increasingly looking at technical solutions to:

- reduce physical strain

- stabilise output quality

- make harvesting work more predictable

This is influencing investment decisions in equipment, layout and workflow design.

3. Data-driven growing gains traction

Yield tracking, flush performance analysis and real-time monitoring are becoming standard tools for larger operations. What stands out: growers are less interested in dashboards, and more in actionable insights that support daily decision-making on the farm.

4. Sustainability: from ambition to optimisation

Rather than big sustainability claims, the conversation is moving toward practical optimisation:

- energy efficiency per kg

- smarter use of substrates

- longer equipment lifecycles

Incremental improvements are proving more impactful than radical overhauls.

What to watch next

In the coming months, expect more discussion around:

- hybrid harvesting as a structural solution

- the ROI of semi-automation

- technology that adapts to biological variability, instead of forcing uniformity

We’ll continue to follow these developments closely and share insights that matter to growers, farm managers and technology partners.

GrowTime recently showcased its high-performance automation solutions during the Umdis mushroom cultivation course at the Marczak mushroom farm in Poland.

Participants could see a presentation of GrowTime lorries equipped with the MycoSense Spotlight system working in real conditions on the farm.

A major highlight was the “smart speed control” feature—an intelligent speed management solution developed through close collaboration between the MycoSense and GrowTime teams. This kind of automation is designed to boost productivity while keeping daily operations more predictable and easier to manage.

It also supports a higher level of workplace safety and helps extend equipment durability in demanding farm environments. With better control over production processes, farms can improve efficiency and see a measurable impact on profitability.

Read the full recap and watch the event video in the article here.

Optimizing Mushroom Harvesting: Advanced Automation for the Fresh Market

Global mushroom growers face rising labor costs and a shortage of skilled pickers. GTL Europe provides a high-tech solution to these industrial challenges. We combine the Automatic Picking Lorry with the Mycosense Spotlight System.

This integration transforms manual harvesting into a professional and data-driven operation.

Intelligent Guidance: The Mycosense Spotlight System

The Spotlight System acts as the brain of the harvesting process. It scans the growing shelves in real-time. Centralized software then projects light points directly onto the mushrooms that require picking.

The lorry uses this data to automatically accelerate or decelerate. This cruise-control function adjusts the speed based on mushroom density. It ensures the picker stays in the most productive zone without manual intervention. The system provides accurate instructions and detailed performance data for the grower.

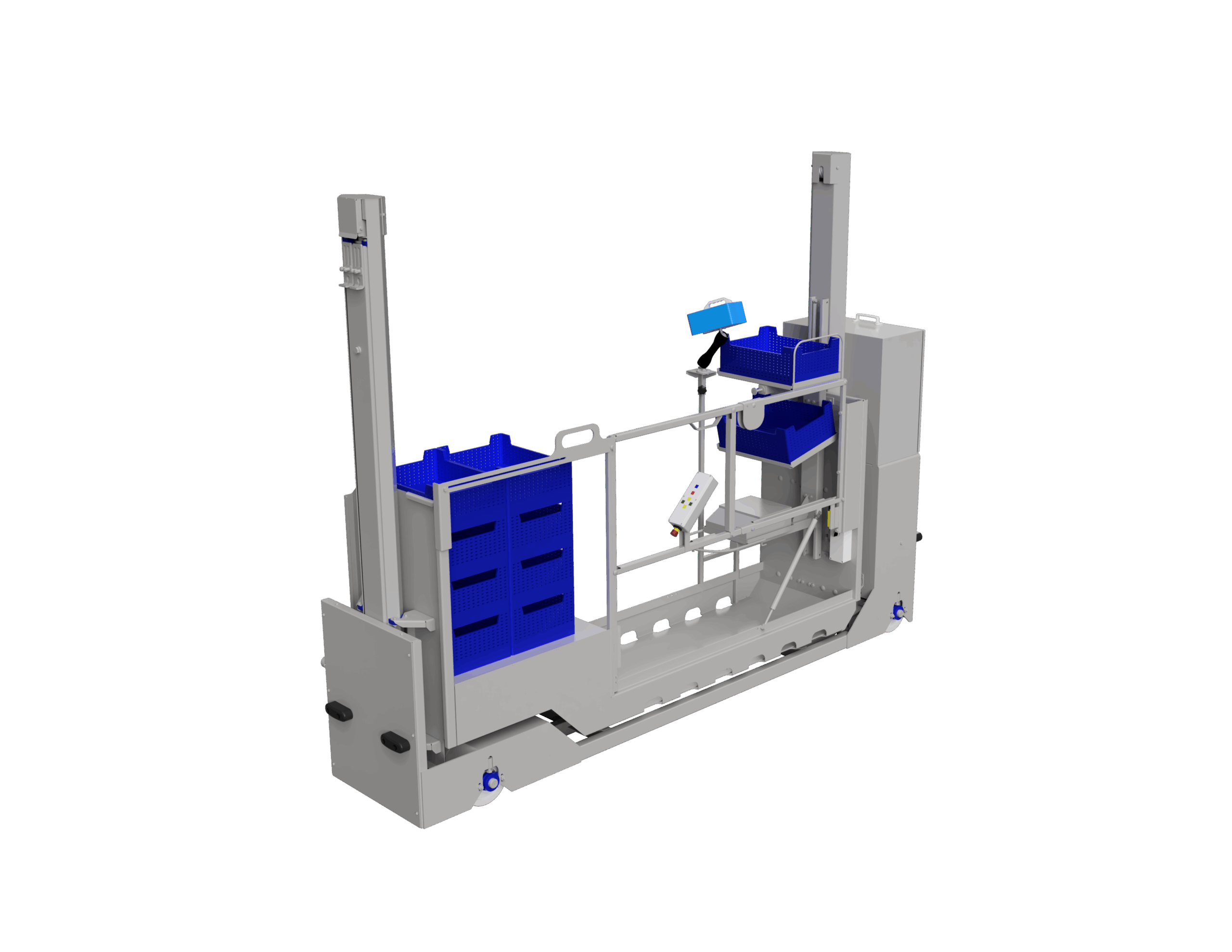

Engineering Excellence: The Automatic Picking Lorry

The GTL Automatic Picking Lorry is engineered for durability and safety. The machine features a robust aluminum frame and a stainless steel work platform. An integrated electric lifting system brings the picker to the ideal working height for every shelf.

A critical component is the integrated harvesting conveyor. It gently transports mushrooms away immediately after they are harvested. This eliminates the need for manual handling of crates or boxes. The machine also includes integrated LED lighting and is prepared for connection to a watering boom.

Intelligence through the Mycosense Spotlight System

The Spotlight System acts as the brain of the harvesting operation. It scans the growing shelves in real-time. Centralized software then projects light points directly onto the mushrooms that require picking.

This guidance ensures that every picker follows the exact instructions of the grower. The system provides detailed performance data and real-time monitoring. This allows for smarter decisions based on reliable facts instead of estimates.

Measurable Efficiency and Yield Increases

Field tests provide clear evidence of the system performance. Growers can expect significant improvements in both output and quality. Key results include:

- A higher yield of +2 to +6% during the first and second flushes.

- A picking speed increase between 10 and 27%.

- Training time for new staff reduced from months to just a few days.

- A significant reduction in picker fatigue and the need for direct supervision.

- Consistent punnet sizes and better-organized growing beds.

- Reliable data as a foundation for smarter decisions.

Implementation in Existing Facilities

GTL Europe designs these systems to be compatible with existing mushroom farms. The transition to automated assistance is straightforward. To implement this technology in an existing facility, the following elements are required:

Shelf Compatibility: The system is designed to work with standard professional shelving systems in modern growing rooms.

Power Supply: Access to a reliable electrical connection is necessary for the charging and operation of the lifting systems.

Software Integration: The centralized control software must be connected to the farm network to manage picking instructions.

Floor or Rail Setup: The lorries can be configured for either floor-running or rail-running setups depending on the current infrastructure.

Engineering Excellence from Venlo

At GTL Europe, we manage the entire production process in-house. Our engineering team in Venlo, The Netherlands, ensures that every component meets the highest standards. We offer full after-sales support and service to ensure long-term reliability. By choosing GTL Europe, you invest in a turnkey solution that brings your facility into the future of mushroom harvesting.

Coating Sprayer - Ribbstyle

Coating Sprayer

Location: The Netherlands

Company: RibbStyle

RibbStyle is looking for a Coating Sprayer to join its growing team. In this role, you apply high-quality coatings in controlled environments, working on both national and international projects.

Profile

- Experience as a sprayer or interest in learning the trade

- Eye for detail and quality

- Willingness to work on international projects

Click here to read more or apply.

Can ChatGPT Grow Mushrooms or Make Compost?

As a mushroom and compost consultant, I receive more questions from clients who have already searched for answers using ChatGPT. Often, they are not looking for a new solution, but for verification of what they have found online. This already shows how widely AI tools are being used in our industry. I use ChatGPT myself on a regular basis. It helps me write reports and articles that are clearer and easier to read, and its English is certainly better than my own “Dunglish” (20% Dutch, 80% English).

For collecting information about composting or growing issues, ChatGPT often provides useful insights. The answers are not always fully correct or directly applicable in practice, but they usually point in the right direction and help identify which area needs further investigation.

Modern mushroom production requires precise control of both composting and growing processes. Small variations in raw materials, fermentation, climate, or handling can have a significant impact on yield and quality.

While practical experience and on-site expertise remain essential, digital tools such as ChatGPT can support growers and consultants with faster analysis and better-structured decision-making. In cooperation with a compost and growing consultant, ChatGPT functions mainly as a knowledge-management and support tool. Combined with biological understanding and field experience, this approach can help improve compost consistency, crop stability, and overall production results.

Total Mushroom Service

Jeroen van lier

( 80%) Chat GPT (20%)

The benefits of hybrid harvesting - Mycionics

Why collaborative robotics make sense in mushroom production

What happens when humans and robots harvest side by side? Not in theory, but in the real, high-pressure reality of mushroom farms, with variable growth, peak flushes, labour shortages and razor-thin margins.

Hybrid harvesting, also known as collaborative robotics, is gaining ground precisely because it doesn’t pretend farming is predictable. Instead of forcing full automation before the technology or the farm is ready, it offers a practical middle path, robots and people working together, each doing what they do best.

For many growers, that balance is exactly what makes automation finally workable.

Why hybrid harvesting matters right now

There is a growing consensus in the industry that fully autonomous harvesting is not yet a universal answer. Mushrooms don’t grow the same way twice. Flushes vary, beds behave differently, and peak moments can overwhelm even the fastest machines.

At the same time, labour pressure continues to rise. Growers are looking for solutions that reduce dependency on manual labour, without taking on the risk of an all-or-nothing automation leap.

Hybrid harvesting answers that tension. It allows farms to automate step by step, task by task, proving value along the way, while keeping humans involved where flexibility, judgment and backup capacity are essential. In short, it lowers risk, increases resilience, and makes automation adaptable to real farming conditions.

What hybrid harvesting actually means

Mycionics defines hybrid harvesting as giving growers control over how much of the harvesting process is done by robotics and how much by people, and being able to adjust that balance when conditions change.

In practice, many robotic systems can handle around 70 to 80 percent of the physical picking work. But the remaining portion often determines profitability, especially during peak flushes, selective picking moments and quality-critical decisions.

Hybrid systems are designed to absorb those fluctuations. When robots reach their maximum capacity, human pickers can seamlessly augment the process. When labour is scarce, automation takes the lead. The system does not fail when reality deviates from the average.

Designing for reality, not perfection

A key reason Mycionics chose a hybrid path is simple. In complex environments, trying to be cheaper, faster and better at the same time usually leads to compromises elsewhere.

Mushroom harvesting involves thousands of micro-decisions per shift. Where to go on the bed. Which mushrooms are at the right stage. How to pick without damage. Where to place product. How to manage containers and flow.

Humans are strong in judgment and adaptation. Robots excel at consistency, precision and repetition. Hybrid harvesting assigns each role accordingly.

Mycionics’ proprietary vision, decision support and crop-intelligence system identifies mushroom size, predicts growth and determines optimal picking moments. These decisions can then be executed either by robotic arms or by human pickers, removing cognitive load from people while preserving flexibility. The result is faster picking, better timing and more consistent quality.

From scanning to packing, a modular approach

Hybrid harvesting does not start or end with picking.

Pre-harvest scanning maps pinned beds, tracks growth over time and predicts when and where harvesting should begin and how to adjust environmental factors to boost yield. Crop Scout guidance points human pickers to the mushrooms that should be harvested first, eliminating guesswork and increasing efficiency.

Robotic harvesting units mounted on drawers or lorries can handle large volumes, placing mushrooms onto belts, conveyance systems or directly into containers. During short, intense flush periods, humans can work alongside the robots to temporarily increase capacity during separation.

After picking, packing makes up about 50% of the labor cost in harvest. Robotic packing systems automate one of the most labour-intensive stages, improving weight accuracy, reducing giveaway and maintaining best presentation quality – “cheaper faster better”!. Because all modules share the same vision and intelligence backbone, growers can scale gradually, investing when confidence and return on investment make sense.

Measurable impact on farms

Early results in side-by-side comparisons on neighboring beds show why this approach resonates. Where growers are using crop intelligence and guided picking see around 15 percent improvement in labour efficiency and 10 to 15 percent yield improvement through better harvest timing.

With robotic harvesting, up to 75 percent of picking labour can be automated using multi-arm systems, with human support during early separation days to set the bed for full automation. Robotic packing significantly reduces labour demand in a stage that often represents around half of total harvest labour costs.

Beyond the numbers, growers value something less tangible but equally important. Systems that keep working when conditions are not perfect and never tire.

The role of AI, and where humans still matter

Machine vision and AI improve with data. The more cycles a system runs, the more accurate it becomes at recognising patterns, detecting anomalies and recommending actions.

Robots do not get tired or inconsistent. Over time, they become highly precise. Humans, however, still outperform algorithms in contextual judgment, especially when something unexpected happens. Hybrid harvesting acknowledges that reality instead of fighting it.

By collecting data early and continuously, growers build the foundation for smarter automation over time, without betting the farm on day one.

Looking ahead, hybrid as the bridge forward

Over the next three to five years, hybrid harvesting is likely to become the dominant automation model in mushroom production. Not as a compromise, but as a transition strategy that works NOW.

As technology proves itself in the field, confidence grows and returns grow. As confidence and returns grow, automation deepens. The system remains flexible, modular and grounded in farm realities.

The guiding principle remains simple. It has to work.

Born out of mushroom farming itself, Mycionics continues to focus on solutions that deliver value immediately, scale responsibly and strengthen the industry as a whole. There is no winner-takes-all model here, only progress that works when everyone can keep up with the harvest.

https://mushroommatter.com/details/itemlist/user/42-mushroommatter?start=0#sigProIdd0a238aee6

E-nema will once again be present at the Mushroom Days in the Netherlands and that's good news for growers striving for strong, uniform, and sustainable crops. As a pioneer in biological crop protection, e-nema has been developing beneficial nematodes for over 25 years, which offer a natural solution to harmful insects in mushroom cultivation.

E-nema has developed a product line specifically for the mushroom industry aimed at effectively combating the sciarid fly (fungus gnat). These nematodes work deep into the substrate, actively seek out their prey, and thus significantly help control the population, without the use of chemicals.

At the Mushroom Days, e-nema will be happy to explain how these living organisms work, how they can best be applied, and the benefits growers experience in practice. Whether you're looking for a more sustainable solution, better pest control, or simply interested in the latest biological innovations, e-nema's experts are ready to answer all your questions.

Visit their booth and discover how natural enemies can be a powerful ally for healthy and future-proof mushroom cultivation.

Possible mechanisms involved in the fruiting of the cultivated mushroom - by David M. Beyer

To induce A. bisporus fruit body formation, a casing layer is applied to the surface of the compost. Without a casing layer, few if any mushrooms will form. Several theories have been proposed over the years to explain why a casing is needed to initiate the fruiting of mushrooms. I will attempt to cover most of the theories, but will not mention the scientists or researchers who proposed them. If the reader is interested in that information, please contact the author.

A variety of materials have been used for casing. Topsoil, clay peat, spent compost substrate, crushed brick, coal ash, rock wool, pelletized recycled paper products, fly ash, coconut hulls, and various combinations of peat-sand, peat-soil, and peat-vermiculite. It is rather difficult to draw a common property from all these materials, which may serve as a trigger for the mechanism to induce mushroom formation. Several theories have been presented to explain the function of the casing layer and the initiation of the fruiting mechanism.

1. Moisture and Pressure relationships: It has been suggested that a macro-climate in the mushroom house and a micro-climate at the bed surface exist, which will create conditions of slow but continuous evaporation without desiccation of the compost. This special water gradient between the compost, casing, and air is claimed to be necessary for the formation of mushrooms. However, this idea is not supported by those who have grown in caves and in certain chambers where relative humidities are 100% and little to no evaporation occurs. Evaporation seems to play a more important role in pin development. The pressure theory suggests that mechanical pressure exerted by the casing on the mycelium initiates the fruiting process. However, this theory does not seem reasonable, where, under conditions of poor ventilation, little or no fruiting occurs, yet the pressure from the casing still exists.

2. Kleb’s or Klebsian theory: This theory suggests that the tendency for fructification in the casing (soil) is caused by the soil being largely devoid of nutrients yet favorable in its external conditions, such as temperature, moisture, and aeration, for the growth of mushrooms. In other words, reproduction in lower organisms, such as fungi, occurs when characteristic external conditions become unfavorable for growth. Exhaustion of the food supply favors reproduction. As the mycelium grows from the nutrient-rich compost into the casing layer, which is nutritionally poor, fructification is stimulated. This theory was tested by drying and grinding compost to a fine dust. The dried compost was rewetted and used as casing on the same compost after a complete spawn run. Normal mushrooms and a good yield were obtained. Similar experiments were performed, and, in all cases, normal yields were achieved. Therefore, it has been shown that this theory of a change in external low-nutrient conditions cannot be applied to the commercial mushroom, A. bisporus.

3. Fruiting Hormone: These theories propose that a substance, possibly volatile in nature, is produced by the mushroom mycelium, which acts as a hormone that stimulates fruiting. In this scenario, the casing layer acts to either increase or decrease the concentration of the “hormone,” ensuring the proper concentration of the substance is reached and maintained to initiate fructification.

One mechanism that was proposed suggested that some volatile substance emitted from the mycelium in the compost and in the casing stimulates mycelial growth and inhibit fruiting. It was suggested that the function of the casing was to provide a medium for rapid oxidation-reduction reactions that would destroy this compound. However, when moist white-silica sand (an inert material) was used as casing material and placed in a high RH chamber to prevent drying, normal mushrooms were formed, and a good yield was achieved.

Other experiments were performed in closed-chamber experiments, which showed that mushrooms do not form unless the air circulated in the system was washed with soda lime, mineral oil, or alkaline KMnO4. A similar closed chamber setup, which recirculated the air while providing provisions for introducing oxygen into the system as needed, was used to demonstrate that when the same air is recirculated into the growing chamber, no mushrooms form. When air was circulated through charcoal, and then back into the chamber, normal production occurred. Air that was washed with soda lime to remove CO2 and possibly some short-chain organic compounds did not form mushrooms. Both researchers showed that a substance produced that is not removed will inhibit the fruiting of the mushrooms.

Another researcher suggested that a high-molecular-weight substance, hormone-like and highly volatile, is produced by the mycelium. The functions of any casing layer are to sufficiently inhibit the volatilization and/or diffusion of the material so that a certain concentration is obtained to provide the stimulus for fruiting in the mycelial network of the compost. This substance and/or other materials, if present in too high a concentration, inhibit fruiting by adversely affecting the rhizomorphs in the casing layer.

4. Carbon Dioxide (CO2): Experiments were conducted introducing various amounts of CO2 into a closed chamber. He found that concentrations above 0.5% caused an inhibition of fruiting. Using more precise monitoring and detection equipment, others found that CO2 concentrations as low as 0.1% had a detrimental effect on fruiting and that different mushroom strains responded differently to different concentrations. From these experiments, a theory was proposed that a partial pressure gradient of CO2 is necessary for fructification of the commercial mushroom. The casing layer is the region where the high CO2 connections meet the low concentration above it. For fructification to occur, they suggested that the level of CO2 above the casing must be less than 0.1% to 0.5%, but the strains used today will fruit at levels above that.

5. Stimulation by microflora theory: Another proposed theory on the initiation of fruiting is initiated by microorganisms. By inoculating fruiting mushroom initials on a petri dish with sterilized compost and casing, it was shown that no fruit body initials formed. However, using non-sterilized casing on the other half of the petri dish, fruiting occurred. It was concluded that a living organism was responsible for initiating fruiting. It was further postulated that these organisms were bacteria, and they lived in the casing. It was suggested that the bacteria were stimulated by volatile metabolites from the compost mycelium, which were oxidized or converted by the bacteria, thus initiating fruiting. Several bacteria have been isolated from the casing layer and proposed to be involved in the fruiting process. Pseudomonas putida has been isolated from the casing, and it was suggested that it was the growing mycelium that released volatiles into the environment of the casing, which allowed for the predominance of this bacterium.

However, several studies have shown that the addition of activated charcoal to the sterilized casing facilitates fruiting. It was suggested that charcoal adsorbs the volatile metabolites of the mushroom mycelium, which controls vegetative growth, thereby eliminating the barrier to fructification. These studies effectively disprove the theory that bacteria alone are essential for the fruiting of A. bisporus. However, bacteria may have an influence on the quantity of fruit bodies initiated during commercial mushroom production. The increase in vegetative mycelial growth and fewer pins in high-temperature pasteurized casing compared to non-pasteurized casing is circumstantial evidence supporting a role for bacteria.

At least six metabolic gases have been shown to be produced by the mycelium of A. bisporus: CO2, ethylene, acetaldehyde, acetone, ethyl alcohol, and ethyl acetate. Although others suggested that acetone was the most important gas, the fungistatic effects of ethylene on many soil-borne fungal pathogens are well known. Substantial levels of ethylene have been shown to be produced from the mycelium, not the fruit bodies, of A. bisporus as the pins were rapidly developing.

The association between lipid metabolism and fruiting in A. bisporus was discovered quite by accident while studying the supplementation of mushroom compost at casing time. While adding materials that would be economically available for growers, researchers discovered exceptional pinning yields when a meal they used contained oil with lipids. Further research has shown that materials containing lipids and oils improve pin initiation and mushroom yield.

Summary

It appears that no single mechanism is responsible for initiating the mushrooms' fruit bodies and determining the quantity of mushrooms that form and develop. Our best guess currently involves the role of microbes and the accumulation of one or more volatiles in the casing layer. Are the microbes producing these volatile compounds, or are they using them in their metabolism, thereby accumulating them in their cells? What is the role of lipids as a nutrient for the mushroom spawn growth, pin formation, and yield? It is known that mannitol plays a role in the osmotic potential gradient between the spawn in the compost and the mushrooms growing on the casing. But is that the only nutrient influencing pinning? Hopefully, someday, research technology will enable us to answer some of these questions and provide growers with more tools to control pin sets, resulting in optimum fresh quality and maximum yields.