Mushroom Matter

Welcome on our platform. Why MUSHROOM MATTER? Because mushrooms play an important role in our lives as well in business. Our goal is to bring the world the very latest mushroom news with the upmost care to support the positioning of our beloved Mushroom.

Now, it is the peak picking season of wild Russula mushroom in Xiangqi Town, Teng County, Guangxi Zhuang Autonomous Region of China.

“Russula mushrooms grow for above 3 times per year, peak production period for each time is at 3-5 days. Each year, Russula massively emerges from August to September,” introduces one of mushroom foragers warmly, adding that now, in Xiangqi Town, purchase price for dried Russula is at 1200-1400 CNY per kg, for dried Russula which carries superior quality, 2000 CNY of purchase price could be reached for per kg.

Russula is a kind of rare medicinal mushroom which gains popularity in domestic and oversea markets for its attractive appearance, tender flavor, high nutrition value and other merits. In China, Russula Vinosa are widely distributed in Sichuan Province, Shanxi Province, Fujian Province, Yunnan Province and other major regions.

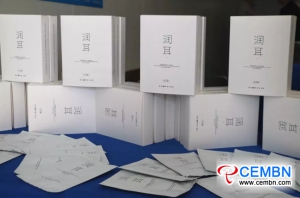

Would like to try this White fungus facial mask?

On the spot of The 7th China (Mianyang) Kejicheng International Technology Expo held in Mianyang City, Sichuan Province of China, Run’er White Fungus Facial Mask developed by Tongjiang Yudeyuan Run’er Biotechnology Co., LTD attracted numerous attendees and visitors.

“With the adoption of modern technology, Run’er White Fungus Facial Mask is also extracted with abundant polysaccharide and amino acid essence of White fungus (银耳), highlighting the manufacturing concept of ‘Green, Healthy and Original Ecology,’” introduces Ms. Liu Xiaomei, manager working in Sales Department of Tongjiang Yudeyuan Run’er Biotechnology Co., LTD warmly.

Tongjiang County of Sichuan Province is known as the birthplace of White fungus and the hometown of White fungus in China, White fungi produced in the county gain popularity both at home and abroad by virtues of thick and tender texture, high nutritional and medicinal value. Over the years, Tongjiang White fungus has been identified as China’s Well-known Trademark by State Administration for Industry and Commerce of the People's Republic of China. And, its brand value was once assessed to reach 3.232 billion CNY.

Mushroom Office and Delphy are discussing further-reaching cooperation to serve growers together in the field of advice and training in the mushroom sector. The intention is to further develop new advice products that connect to the digitization of cultivation. The demand for more digital advice and education and training is high. Both parties are of the opinion that Dutch mushroom cultivation continues to play an important role in the global playing field, whereby the demand for knowledge and training will continue to exist in the Netherlands. Delphy and Mushroom Office will continue their ongoing activities until the realization of the collaboration.

The aim of the collaboration is to join forces and offer added value from both specialisms in the areas of:

- Data-driven cultivation. The use of data to optimize the cultivation of mushrooms.

- Joint range of courses and training courses.

- Setting up projects with the aim of increasing innovation in the mushroom sector.

For further questions, you can contact:

Cees Oele, This email address is being protected from spambots. You need JavaScript enabled to view it.

Or Mark den Ouden , This email address is being protected from spambots. You need JavaScript enabled to view it.

According to mushroom quotation provided by Gansu Lanzhou Zhangsutan Vegetable Wholesale Market, on September 11, King oyster mushroom, Shiitake mushroom, Superior Shiitake mushroom, White beech mushroom, Brown Shimeji mushroom, Agrocybe cylindracea and Button mushroom are 7 mushroom varieties that show price rise.

1. Price of King oyster mushroom has risen from 6.5 to 6.8 CNY per kg, indicating 5% of increase range.

2. Price of Shiitake mushroom has risen from 10 to 12 CNY per kg, indicating 20% of increase range.

3. Price of Superior Shiitake mushroom has risen from 14 to 15 CNY per kg, indicating 7% of increase range.

4. Price of White beech mushroom has risen from 13.3 to 16.7 CNY per kg, indicating 26% of increase range.

5. Price of Brown Shimeji mushroom has risen from 18.3 to 21.7 CNY per kg, indicating 19% of increase range.

6. Price of Agrocybe cylindracea has risen from 13 to 14 CNY per kg, indicating 8% of increase range.

7. Price of Button mushroom has risen from 11.5 to 14.3 CNY per kg, indicating 24% of increase range.

On the contrary, by September 11, Oyster mushroom and Seafood mushroom are 2 varieties that show price fall.

1. Price of Oyster mushroom has dropped from 7 to 6 CNY per kg, indicating 14% of decline range.

2. Price of Seafood mushroom has dropped from 9 to 8 CNY per kg, indicating 11% of decline range.

“Price of Enoki mushroom is at 5 CNY per kg. Recently, price of the majority of mushroom is rising at a small range in our market. Besides, as Moon Festival and National Day approach, mushroom producers are striving to enhance the quantity of supply, hence price of mushroom is expected to stay stable in future time,” introduces manager of Gansu Lanzhou Zhangsutan Vegetable Wholesale Market warmly.

On September 10, farmers working in mushroom cooperative in Liubo Village, Fengkuang County, Hunan Province of China are engaged with picking work of fresh Shiitake mushroom.

“Rich harvest of Shiitake mushroom brings about handsome incomes and lifts our quality of life,” said one of farmers passionately, adding that now, the cooperative holds the cultivation scale of 100,000 sticks of Shiitake mushroom, daily output on fresh mushroom comes to over 2500kg while the present wholesale price is at 6-10 CNY per kg.