Mushroom Matter

Welcome on our platform. Why MUSHROOM MATTER? Because mushrooms play an important role in our lives as well in business. Our goal is to bring the world the very latest mushroom news with the upmost care to support the positioning of our beloved Mushroom.

The hands that grew a brew are now raising fungus for survival in northern West Bengal. Sabitri Toppo and Mausumi Minj are among 700 plantation workers who lost their jobs when the Madhu Tea Estate in West Bengal’s Alipurduar district.

The tea estate is one of 26 in the district’s Kalchini block, many of them in a bad shape due to low yield, quality and labour issues.

“We formed a cluster of women from 50 families, some of them from the closed tea estate, and trained them in organic mushroom farming more than a fortnight ago. We also provided them a permanent mushroom-growing shed and home-delivered spawn,” Binoy Dhar, a farm specialist with the Assam-based Mushroom Development Foundation (MDF) told The Hindu from the Kalchini area.

Please read the full article here.

Ditch the detox and eat more mushrooms

If you’re like most people, setting a new year’s resolution that involves health and wellness is something that was on top of your 2022 to-do list.

If you’ve found yourself failing at accomplishing these goals in the past, it may be time to move away from a detox type or other quick fix type dietary approaches, and instead embrace the steps needed to fill the fridge with real food and start eating in an intuitive way.

Detox and restrictive type diets simply don’t work, they are not sustainable and overlook the fact that your body’s liver, kidneys, skin and lungs are already doing the job needed to detox and eliminate waste on a continuous basis. Trying to shed weight quickly, via a drastic cut in your usual calories or kilojoules, will generally back-fire. As your body thinks you are starving or in a famine type scenario, it will try to fight back. This is done via slowdown in your metabolic rate (how fast you usually burn the food kilojoules or calories you eat). It also means any initial weight loss, will be regained a lot quicker and then a lot harder to take off the next time around. The bottom line is that you will go a lot further if you focus on habits that allow you to implement nutritious foods into your diet, rather than restricting and cutting out superfoods such as mushrooms.

Please read the full article here.

Source: AMGA / Australian Mushroom Growers´ Assoc.

Mushroom picking - ergonomics and profitability

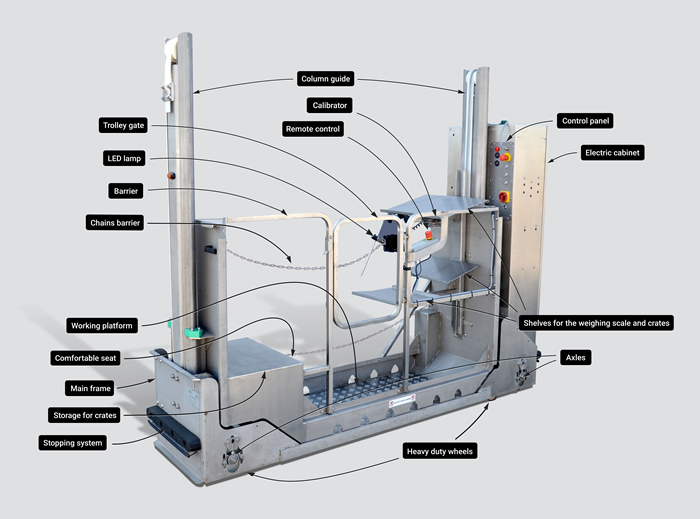

More than 13 years of discussions with mushroom growing farm owners around the world convinced us to make one statement: one of the main factors generating significant costs for mushroom growing farms is workers' wages, and they work most efficiently (they pick faster and more with relatively less fatigue) when optimal working conditions are created for them.

It is no secret that the worker who picks mushrooms spends most of the day on the platform of a mushroom picking trolley, and its proper construction is the key to facilitating the daily work.

Below are some of the factors that determine, in large part, whether after a day of hard work your employees are still productive and will easily return to work the next day or whether they feel physically exhausted and their productivity is simply low.

- The ease of reaching the mushrooms through a smooth, automatic movement up, down, right and left - the essence of the work of the person who picks the mushrooms is to reach the mushrooms which have grown to the right dimensions quickly and easily. The difference between manual, semi-automatic and automatic solutions is crucial: time and difficulty in moving. Automatic solutions (trolleys with a suitable platform) allow to reach the mushrooms more easily while saving energy of the picker.

- Appropriate adjustment (height, inclination, distance) of the shelves for mushroom containers. In addition to reaching the right mushroom, it needs to be picked and then put in a container. Shelves for packaging / boxes should be properly adapted to the figure and range of motion of the person picking the mushrooms. Facilitating this activity means faster and less tiring picking, and we are talking about an activity that is repeated every day even thousands of times!

- Seat adjustment. The height of the "seat" and the distance from the box/package shelves should be adjustable in order to be able to adjust it to the distance from the mushroom containers, but also above all to the height of the person who picks the mushrooms. Comfortable body placement means less fatigue and less fatigue means faster and more efficient work.

- Perfect shape and thickness of profiles. Most mushroom carts have rails that not only protect against falling out, but above all should have a geometry that also facilitates the motion / movement of a person on the platform, facilitating movement on the platform, supporting the employee who repeatedly holds onto them while standing up or sitting down. Rails should be of adequate strength and preferably rounded, ergonomic shape to ensure safety and enable a solid hand grip.

- Location of the pilot and brake. A modern picking trolley is controlled by an intuitive remote control, which should be placed in such a place that it is easy to access (without straining the body, without unnecessary movements) and allows controlling it with both hands.

- Trolley components which are subject to maintenance and assembly/disassembly. Part of the daily work of the mushroom picker is also the preparation of the trolley for work by assembly or disassembly of the drive and washing and disinfection of the elements of the trolley. Good mushroom picking trolleys are designed for these activities to be performed quickly, easily (without requiring specialized personnel) and without undue impact on the wear of the trolley components.

- Easy, possible picking from the bottom shelf of the shelving. Non-customized solutions (choosing the wrong design of the trolley) may result in the necessity of additionally strenuous, physical work on the picking of the mushrooms from the bottom shelf of the shelving or prevent any picking at all, because the floor of the trolley platform is located too high to be able to easily reach this shelf from the platform. It is worth choosing such trolleys that will enable ergonomic picking from all shelves of the shelving, including the last one.

The key to optimizing the efficiency of harvesting in a mushroom growing farm is the choice of such devices that will actually speed up and facilitate the work of employees, because in the vast majority of mushroom growing farms around the world, it is the human resources that constitute one of the largest fixed costs of the mushroom growing farm's operation.

It is a common mistake to choose the cheapest trolleys, not the ones that are best thought out in terms of construction and enable the most ergonomic, and therefore efficient, work for our employees. By choosing a better, and therefore usually more expensive, solution, we can save a lot, because the process of mushroom picking will ultimately turn out to be much cheaper using the potential of the right devices.

—

The article’s author is GROWTIME (growtime.eu), a manufacturer of high-end mushroom picking trolleys used by leading mushroom growing farms around the world. If you are interested in mushroom picking trolleys, then check out our leading products:

● Mushroom picking trolley PASCAL - https://growtime.eu/en/produkt/pascal-picking-trolley/

● Mushroom picking trolley NEWTON - https://growtime.eu/en/produkt/newton-picking-lorry/

It looks like we are not going to have any winter this season in Europe. On the contrary. It is very wet and humidity is very high.

This has its reflection on compost and casing.

If raw materials for compost are stored outside or under just a roof, they are evaporating less water and in the same time some materials get wet by the rain.

What really matters in mushroom picking in mushroom growing farms?

Almost every professional, prosperous mushroom growing farm uses specially designed trolleys for mushroom picking. This is very important because it’s the labor cost of the employee and its optimization that are crucial for owners of mushroom growing farms.

A well-designed trolley supports the picker by allowing them to pick mushrooms very quickly while maintaining a minimum of physical effort, which is after all necessary to carry out the harvest in an optimal way.

Trolley manufacturers around the world are trying to deliver increasingly efficient trolleys. Efficient, i.e., those that maximize the speed of the picking while maintaining durability, ergonomic and safety of the employee.

What solutions does a modern mushroom picking trolley offer?

For an owner of a mushroom growing farm, the solutions that directly accelerate mushroom picking are the most important ones and they include, among others:

- movement of the platform to the right and the left is crucial so that the worker can move along the shelving automatically;

- the platform must be powered fully automatically so that the trolley does not need to be moved manually, and for this purpose, the best solution seems to be a simple remote control where the worker selects the "front" or "back" button;

- it is important to move the trolley up and down because the racks have many shelves, and the employee should not waste time and energy to reach them physically (all this should be easily managed in one place from the control panel);

- in the case of upward and downward movement of the platform, it is important that the trolley is made in such a way as to also enable ergonomic picking of mushrooms from the bottom shelf of the shelving;

Another important factor affecting performance is the power supply of the trolley:

- we use batteries, and these must be characterized by an optimally short charging time and very high capacity, so that the employee can operate without interruption even for several dozen hours (but also, they cannot be too heavy and large for them to still remain mobile)

Small but important improvements come in handy:

- good lighting from the trolley, because during the picking, the employee constantly evaluates whether the mushroom is suitable for picking or not, and the better illuminated shelves the less tired the picker's vision;

- weight shelves and mushroom containers, preferably large and adjustable, to adapt them to the conditions and standards of the country concerned;

Accidents at work equal the cost of time-off and sickness, so good trolleys must be safe. Examples of top-quality trolley safety features include:

- anti-fall guardrails which prevent the operation of the trolley without closing them,

- safety brakes which stop the trolley itself when it hits an obstacle or during a potential uncontrolled fall of the platform;

- protection against cutting the hand or arm of the picker during platform manipulation;

- non-slip platform, which makes moving in humid conditions less risky;

- the overall design of the trolley made at minimum in accordance with the safety regulations covered by the CE Machinery Directive

Click here for larger size image.

What is selective picking and what are its results?

What is selective picking and what are its results?

Selective picking is the synergy of the traits associated with the trolley’s mobility. The key to a mushroom growing farm’s profitability is to provide an employee with solutions that allow them to quickly and easily reach those mushrooms that are already ready for picking.

Faster and therefore easier access to mushrooms that are ready for picking means higher harvesting efficiency, and our calculations show that mushroom growing farms using modern trolleys are able to increase yields by up to 2 kg of mushrooms per m² of crop and reduce the employment rate by an average of 10% to 20% and more.

Where to look for trolleys that will ensure maximum profitability of a mushroom growing farm?

The author of the above content is GROWTIME - a manufacturer of mushroom picking trolleys, which incorporate all the above-mentioned solutions and even some more. Here are the two most important products you should look over:

Mushroom picking trolley PASCAL - https://growtime.eu/en/produkt/pascal-picking-trolley/

Mushroom picking trolley NEWTON - https://growtime.eu/en/produkt/newton-picking-lorry/

Another special year has passed for E-nema

The crisis teaches us to appreciate what seems to be taken for granted again and to reflect on a vital force:

TRUST

Without trust in ourselves and others, our actions would be blocked by constant safeguarding, doubting and weighing up. Fear would paralyze us. “We should fear nothing more than fear itself”. With these words Franklin D. Roosewelt sowed new confidence 90 years ago and proclaimed the "New Deal" in the USA.

The “New Green Deal” in Europe is now supposed to trigger a similar mood of optimism.

The growing importance of biological crop protection is a sign of this optimistic mood and, thanks to the mutual trust in our customers, has allowed our company to continue to grow. We were able to expand our production capacities, welcome new employees and initiate further construction projects.

We would like to thank the mushroom producers for the joint work on the transformation towards a sustainable, organic economy and wish you and your families a peaceful, reflective holiday.

Team e-nema

https://www.nemycel.com/

Why Mushrooms Make the Perfect Gift for Christmas

With this year’s reunions set to be extra special, December is a wonderful time for catching up with our loved ones, swapping gifts, and indulging in feasts together. Of course, with all the celebrations, Christmas isn’t always a good time for our health (or the scales)!

We know that by simply adding mushrooms to our Christmas stuffing, to chip and dip platters for entertaining, and including mushrooms in summer BBQ recipes is a great way to serve lighter, healthier and tastier meals this festive season - but there are also very specific reasons why mushrooms are a great health gift to give your loved ones this Christmas.

White Mushroom Cups – The gift of vitamin D.

The white mushroom cup is on the top of our Christmas tree, as it is Australia’s most popular festive mushroom - with good reason. Despite its small size, exciting new Australian research1 has uncovered that this little mushroom is full of B group vitamins (including B12), minerals, antioxidants, and gut health nutrients. The research also confirmed something very exciting - mushrooms are the only wholefood able to provide 100% of the daily recommended dose of vitamin D per serve.

Presenting as an active hormone called ergosterol, mushrooms can produce vitamin D in a similar process to our skin. When mushrooms are exposed to sunlight for just 15-minutes the ergosterol converts into a bioactive form of vitamin D, which we absorb when we eat the mushroom. Amazingly, once a mushroom has been ‘supercharged’ with vitamin D by being exposed to the sun, the new D levels remain in the mushroom for up-to a week if they are stored in the fridge.

Please read the full article here.

Source: AMGA / Australian Mushroom Growers´ Assoc.

Keep an eye on the ball

At the end of a year or at the start of a new one it is always a good thing to look back and forward. Look at it as an evaluation and re-focussing of targets. It is also a good time to give yourself and your team a feedback.

Looking back to 2021 it was a year of great challenges. We had our normal variations in compost and casing soil quality. It still is impossible to predict the weather so we still will have to cope with changes in raw materials due to the weather. And reacting to that always comes too late.