Mushroom Matter

Welcome on our platform. Why MUSHROOM MATTER? Because mushrooms play an important role in our lives as well in business. Our goal is to bring the world the very latest mushroom news with the upmost care to support the positioning of our beloved Mushroom.

Dutch Mushroom Days 2022 are cancelled

The Dutch Mushroom Days, scheduled for 6, 7 and 8 July have been cancelled last Friday by the organizers. Main reason for this decision was the cumulative cancellation of leading exhibitors.

“The number of cancellations by the Dutch exhibitors in particular has become so great that, after a weighing of interests, according to (the board of) the Mushroom Days Foundation, the success of the Mushroom Days 2022 is jeopardized. Without participants, the Mushroom Days cannot serve as a platform for meetings and knowledge exchange and the benefits no longer outweigh the costs. The board of the Mushroom Days Foundation therefore has no choice but to cancel the Mushroom Days 2022 for good”

With these words, the board announced the cancellation of the Mushroom Days last Friday the 15th. Some exhibitors expressed their concerns in March this year and advised to postpone the Mushroom Days to 2023. Main reasons for these concerns were and still are COVID (travel) restrictions in some regions in the world, especially in China. Travel restrictions would have a negative impact on the participating exhibitors but also on the event visitors. The other concern is currently how the situation in the Ukraine will further evolve. The negative financial climate is worrying people and bringing a lot of question marks as well. Next to this the timing of the Mushroom Days in July is not ideal.

These concerns were communicated to the organization, however positive signals on the other hand led to the decision to go ahead with organizing the event. A lot of discussions took place, as a group of exhibitors felt not heard by the organization, to consider postponement of the Mushroom Days to 2023. As a result of this, the organization was confronted by more and more cancellations of leading exhibitors which created a stripped-down exhibition floor. The revenues could not outweigh the costs anymore so the choice to cancel the event had to be made.

The organization is informing all exhibitors and visitors and is looking into the financial consequences for all those involved.

This situation is deeply regretted by the leading exhibitors and the organizers as well, but they also expressed looking forward to next year, when the circumstances are hopefully much better.

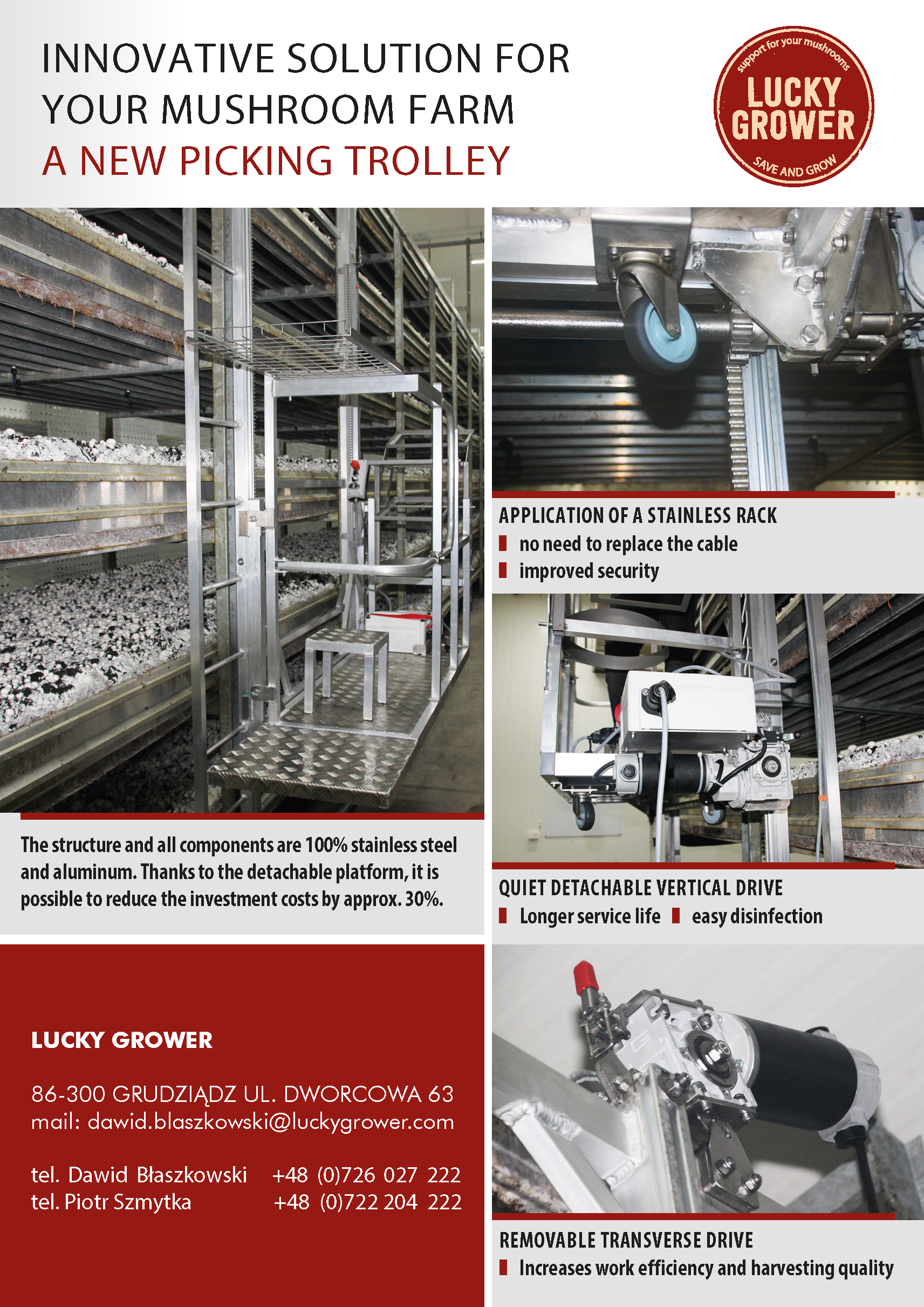

Lucky Grower picking trolley

Mushroom picking trolley for the lowest beds optimizes the picking process from 1st and 2nd bed.

Powerfogger 60 Champignon

The user-friendly Powerfogger 60 Champignon has been specially developed for the disinfection of mushroom cultivation chambers.

• Very effective for indoor disinfection

• Ideal for fly control

Characteristics

This robust device makes it possible to dis- infect chambers quickly one after another with only one tank fill. The unique fogger disperses very fine droplets, which spread evenly and quickly. The droplets contain a high quantity of agent and little water, so a lot of active substance can be applied with a minimal water consumption.

Technical data

Power: 1,5 kW electric motor

Fluid tank capacity: 60 l (fully emptied) Output: approx. 25 l/h

Effective fog range: 60–80 m Adjustable droplet size: 10–20 µm Mechanical steering clock.

Which factors determine the pH value?

My previous blog described what the pH should do during the composting process. This blog examines the role of the raw materials, such as ammonium sulphate, gypsum and water.

The Ukraine grew about 70,000 tons of mushrooms and about 350 mushroom, oyster farms in 2021.

Due to the Russian invasion and in several cases, rockets hitting mushroom complexes and causing partial destruction, about half of the mushroom farms were forced to stop. Ukrainian mushroom growers that stayed behind, continue to harvest where possible and support the army and the population.

Compost production

Of the seven largest composting plants in Ukraine, two ceased operations altogether and were forced to evacuate staff. Five others stopped producing new batches immediately after the fighting began, and in some cases disposed of what was already in production. Thus, the composting plants, which are still working, have the opportunity to ship compost for another week or two.

Peat

Peat for mushroom growing has become a particular problem, as the main deposits of peat, and, accordingly, the production of so-called "casing soil" are in the north of the country, where the situation is very turbulent. Therefore, most of the casing soil production stopped shipping from the first days of hostilities. As of March 15, it is known that some of them have started offering peat, but the situation remains unstable.

Logistics

Mushroom farms and compost production reported that the cost of delivery of peat, compost and mushrooms increased by 2-3 times. In addition, it is difficult to find transport, and a significant number of regions remain almost inaccessible for delivery there and there.

Mushroom farms

About half of the mushroom farms have completely shut down, in many cases simply by turning off the lights and evacuating. Other farms, in areas where the situation was calmer (often this means that missiles and fighters fly directly over the roofs, but do not drop bombs directly in the village), continued to harvest. Much, or even all, of farmers hand over their products to the army or as humanitarian aid to the population.

Source and for more information:

Maksym Yenchenko Mushroom Information Agency "UMDIS"

Telephone: +380-67-506-45-21

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Website: www.umdis.org

Photo: from the Rio Champignon Facebook page

TenCate Toptex® Straw Cover

TenCate Nicolon nets (Tunnel-glide-growing nets) are known worldwide for its performance and reliability and became the standard for the mushroom composting and mushroom growing industry.

Besides the nets, TenCate produces TenCate Toptex® Straw Cover, the essential cover to protect your expensive straw and keep the high quality.

The main component of mushroom substrate/compost is wheat straw. Structure is one of the properties that straw brings to the compost and it also creates a water buffer. Due to the composting process the waxy layer surrounding the straw is removed and the straw is able to absorb water.

Thanks to its continuous fibers, the TenCate Toptex® fleece offers a very low water absorption capacity. Coupled with very fast drainage of rainwater and its enormously high air permeability, this fleece stands out as a permanently reliable and proven storage method. The protective fleece can be used on both sides. The UV and thermal stabilizers contained in the fleece keep it durable for many years, even under high solar radiation. A service life of over 10 years is not uncommon with careful handling. When covering, it is important to ensure optimum tensioning – the fleece must be tightly tensioned at all times.

TenCate Toptex® protection fabric protects straw bales reliably against wind and rain, providing effective respiration. The high quality of the straw is preserved throughout the whole winter season, drying off after heavy rainfall, and the development of mould is avoided.

THE BENEFITS OF TENCATE TOPTEX® (More information at www.toptex.eu)

- Permeable to air and vapour (avoids mould development)

- Water shedding (drains off water at slope angles >45°)

- Resistant to wind lifting, the straw dries off even after heavy rainfallHigh tensile strength and tear resistance (withstands even strong winds)

- UV stable

You can also watch their video here.

Gentle on the Planet

Stakeholders across the food product supply chain are increasingly interested in understanding the environmental effects of food production. Mushrooms have a unique growing process unlike any other produce item and are considered “one of the most sustainably produced foods in the United States1.” Consider this:

- They are grown in the absence of sunlight in a climate-controlled environment.1

- One pound of production requires only 1.8 gallons of water; 1.0 kilowatt hours of energy; generates only .7 pounds of CO2 equivalent emissions.1

- Up to 1 million pounds produced on just 1 acre.1

A 2018 study2 published in the International Journal of Life Cycle Assessment looked at the cradle-to-gate life cycle environmental impacts of mushroom production in the United States from cultivation to harvest and preparation for bulk packaging. The goal was to create a “baseline” estimate of energy use, global warming potential (GWP), water use, and other common environmental impacts.

Please read the full article here.