Mushroom training and courses

Casing soil

Dec 17,

2024

Why is casing soil used? There are two main reasons: 1. the Pseudomonas putida bacterium; 2. to regulate evaporation. Mushrooms will not grow without evaporation.…

Preserve structure during composting

Nov 15,

2022

Longer pre-wetting of straw to preserve structure during mushroom composting In my 'Pre-wet' blog, I already wrote about the importance of pre-wetting for good mushroom…

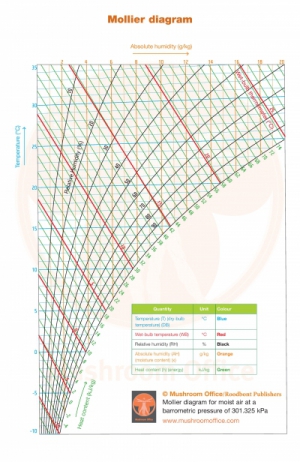

Mollier Diagram

Jun 29,

2022

What is the absolute moisture content of the air? Or the enthalpy of the air? More and more growers have a handy app that reads…

Which factors determine the pH value?

Mar 23,

2022

My previous blog described what the pH should do during the composting process. This blog examines the role of the raw materials, such as ammonium…

Chicken manure

Jan 26,

2021

Chicken manure is an important raw material in mushroom compost and for the composter as it is the biggest source of nitrogen. It is therefore…

Floor humidity and the effects

Jul 01,

2020

Floor humidityIf you want to maintain a natural climate in the growing room during the recovery period until about five days after ventilation you should…

Higher Filling

Mar 02,

2020

Does a higher filling weight give better quality?The filling weight, i.e. the number of kilos of compost per square metre, should be between 80-95 kg/m2.…

Filling the growing room

Jan 23,

2020

How mushrooms grow and the yields are determined at filling. Assessing the compost and casing soil determines the final quality of the mushrooms. After this…

Dry bubble disease

Aug 27,

2019

Dry bubble disease may cause a lot of problems because the spores spread quickly. It’s essential to identify and remove the first affected mushrooms to…