Mushroom Matter

Welcome on our platform. Why MUSHROOM MATTER? Because mushrooms play an important role in our lives as well in business. Our goal is to bring the world the very latest mushroom news with the upmost care to support the positioning of our beloved Mushroom.

Supercluster funding supports world first end-to-end robotic harvesting platform

Next Generation Manufacturing Canada (NGen), the industry-led organization behind Canada’s Advanced Manufacturing Supercluster, has announced almost $4.2 million in collaborative funding for a multi-partner project, led by Mycionics, that will deploy advanced robotic solutions to revolutionize the mushroom harvesting processes.

Mycionics, in partnership with Whitecrest Mushrooms Ltd. and Piccioni Brothers Mushroom Farm Ltd. will deploy and demonstrate the commercial viability of the Mycionics robotic harvesting system. The Mycionics system will fully automate mushroom harvesting using novel advanced robotics and automation. The entire harvesting process will be optimized through the application of data analytics, machine learning and artificial intelligence. Mycionics will be the first company in the world to successfully automate the end-to-end mushroom harvesting process for the fresh market.

“This is exactly the type of project we aim to support through the Innovation Superclusters Initiative,” said the Honourable François-Philippe Champagne, Minister of Innovation, Science and Industry. “Leading-edge Canadian companies like Mycionics promote Canadian solutions to global problems. This project pushes technological boundaries, develops advanced manufacturing and creates good jobs for Canadians while exporting groundbreaking technology to the world.”

As a complete system, Mycionics robotic harvester will increase the yield of a growing room through a “smart graze harvesting” strategy, picking over a 24-hour period and allowing the system to pick each mushroom at the optimal time instead of being restricted to harvesting only during normal working hours. Additionally, the ability to harvest robotically and the use of data analytics will increase food safety, traceability and disease detection.

As Mycionics grows and develops as a company, they will create numerous high-tech jobs in rural communities in Canada and around the world. The company is poised to see significant growth as they begin servicing farms throughout North America and Europe.

“This project serves to highlight exactly what NGen hopes to achieve through its supercluster project funding,” said Jayson Myers, CEO, NGen. “The Mycionics project brings together multiple partners from different sectors of the economy to develop and build a world class advanced manufacturing solution. In the process, Mycionics will create jobs, establish a Canadian supply chain for machine parts and assembly, help build out the entire advanced manufacturing ecosystem, and have a lasting and positive impact on Canadians and the economy.”

“Our partnership with NGen will accelerate commercialization of Mycionics patented robotic mushroom harvesting to solve the increasing labour shortage affecting mushroom farms globally. Mycionics robotics were designed to simply integrate with existing mushroom farm infrastructure commonly used throughout the world.” Michael Curry, CEO, Mycionics.

This is one of many projects funded by NGen through Canada’s Innovation Supercluster Initiative. NGen is investing $192 million of Supercluster funding and is aiming to leverage at least another $358 million of industry investments in collaborative industry-led projects before the end of March 2023 to facilitate collaboration and accelerate the implementation, scale-up, and commercialization of advanced technologies for manufacturing in Canada.

About NGen - Next Generation Manufacturing Canada

NGen is the industry-led not-for-profit organization that leads Canada’s Advanced Manufacturing Supercluster. Its mandate is to help build world-leading advanced manufacturing capabilities in Canada for the benefit of Canadians. NGen works to strengthen collaboration among its membership of more than 3,500 manufacturers, technology companies, innovation centres, and researchers, and provides funding and business support to industry-led initiatives that aim to develop, apply, or scale-up transformative manufacturing solutions in Canada for commercialization in global markets.

About Mycionics

Mycionics is dedicated to empowering mushroom farmers through the use of our robotic harvesting system that performs the labour-intensive work of harvesting mushrooms for the fresh market. Our solution provides mushroom farms of any size with a competitive edge against the global labour shortage afflicting the industry.

Mycionics’ globally patented robotic harvesting system continually picks, packs, and weighs mushrooms that meet fresh market quality and size requirements. Based on the farmer’s harvesting requirements, such as desired mushroom sizes, stem length, quality, harvesting schedule, and more, our mobile robotic harvester scans the mushroom beds, picks the desired mushrooms, trims the stems, and intelligently packs the mushrooms into boxes where they can be retrieved by the farm operators. In addition to our system’s harvesting capabilities, the data collection provides valuable insight into the farms existing growing and harvesting metrics, leading to better agronomic, commercial, and operational solutions for the farm.

Source: Next Generation Manufacturing Canada (NGen)

We are happy to announce that Mertens Mushrooms from Holland has joined our mushroom community!

As a dedicated supplier, Mertens believes in good cooperation towards a healthy growth for every business. The company is well versed in professional agriculture, garden retail and landscaping, and passionately shares its expertise. From its roots in Limburg (The Netherlands), Mertens has developed into a down-to-earth, involved, and most of all reliable and knowledgeable partner.

Mertens has almost 70 years of experience, relies on a team of about 130 permanent employees, has its own vehicle fleet and over 7,000 products in stock. From this basis, Mertens has managed to acquire a leading position in the mushroom sector. When it comes to mushrooms, Mertens is even the world’s biggest player. Our team is active in 41 countries, spread over six continents.

Focus on prevention

Mertens offers a complete package of products for growers and tunnel companies: biocontrol, films, cultivation, compost and sliding mats, fogging equipment, scales and hygiene products. Mertens’ range clearly reflects the trends and developments within the sector, in which prevention is now paramount. Today crop protection products, mainly biological, are only used when absolutely necessary. An example of prevention within mushroom cultivation is the use of nematodes; this worm species plays an important role in the control of mosquitoes in cultivation. Mertens has guided growers intensively in the application of these nematodes. To be able to inform its customers in the best possible way, Mertens ensures that its own expertise is always kept up-to-date.

International growth

From its roots in Limburg (The Netherlands), Mertens’ mushroom branch has increasingly focused abroad. Mertens is now also active in the growing mushroom market China, often indirectly through other supplies or consultants. This is a logical development, knowing that the number of Dutch mushroom growers has decreased drastically in recent years. The extensive online communication possibilities facilitate remote contact. In addition, the Mertens website is a source of information and provides a sophisticated ordering system for both domestic and foreign customers. Among other things, mushroom growers can find order lists, safety sheets and product information here. Online sales have grown strongly in the last few years, but Mertens also attaches great value to personal contact.

Mertens is ready to help you!

Moving with the times, synergy with other sectors, cooperation, flexibility, adaptation to market needs… These are the characteristics that have brought Mertens to where it is today, and all this is combined with expert advice.

Meet our Mushroom Team! They will be happy to help you.

Today in the leading role the 'King Stropharia', commonly known as the wine cap mushroom. This mushroom gets its name from the rich wine-red color and knows its origin in North America. The King Stropharia reaches 20 cm high and has a reddish brown rounded to flattened cap that can become 30 cm wide, therefor the name 'Garden Giant' or 'Godzilla Mushroom'. The gills have initially a pale color, then become gray and finally dark purple-brown. The firm flesh is white, as is the high stem that bears a wrinkled ring. King Stropharias have a delicious rich mushroomy flavor with undertones of potatoes and red wine and the stem has an asparagus-like texture. These delicious mushrooms are extremely low in sodium and calories, as well as fat and cholesterol free. They also contain iron, protein and calcium, making them a healthy addition to your meal.

Read all about this wonderful mushroom here.

We are happy to announce that Lucky Grower from Poland has joined our mushroom community!

Lucky Grower is a professional company that equips mushroom farms around the world, and is known for their knowledge of the industry and understanding of their customer’s needs. The company specializes in picking lorries, growing nets, led lamps and shelvings.

Since 2002, they have been operating as a contractor for mushroom picking machines, but also for drilling rigs, specialized commercial vehicles or complex building structures.They have been subcontracted to several mushroom farm companies in Poland and abroad. They also provided a full range of equipment to more than 20 countries in Europe and other continents.

Please read more on their website here!

Location

e-nema GmbH produces useful nematodes for biological crop protection.

Our location is in the far north of Germany, where the nematodes are produced and shipped worldwide.

Markets

Our main sales markets are currently in European countries such as Germany, Benelux, Poland, Ireland, Austria, Switzerland, Bulgaria and Romania as well as in North America. Eastern Europe and other countries such as Hungary, France, Italy, Spain and Georgia are becoming increasingly important. But Australia, New Zealand and Africa are also looking for biological alternatives to chemical crop protection and are increasingly using our nematodes.

Customers

Our customer portfolio ranges from major global customers to medium-sized companies and end customers. This includes professional users from agriculture, fruit and horticulture as well as private users from the home and garden area. We rely on close cooperation with our strong and well-networked partners.

Our customer portfolio ranges from major global customers to medium-sized companies and end customers. This includes professional users from agriculture, fruit and horticulture as well as private users from the home and garden area. We rely on close cooperation with our strong and well-networked partners.

The quality of our offered products should meet their requirements and enable them to operate profitably and sustainably. We maintain close contact with our partners and customers and are interested in long-term cooperation.

We also have customers in the global mushroom industry who value organic crop protection. Consumers are increasingly paying attention to residue-free goods and more and more chemical agents are losing their effectiveness or are being banned by the EU.

We offer the worldwide mushroom industry a successful biological solution to the problem of fungus gnat control in mushroom cultivation.

Our product nemycel® is already being used very successfully in professional mushroom cultivation. It contains the insect-pathogenic nematode Steinernema feltiae, a naturally occurring nematode that has specialized in the larvae of sciarid gnats, among other things.

Learn more about the product:

https://www.nemycel.com/

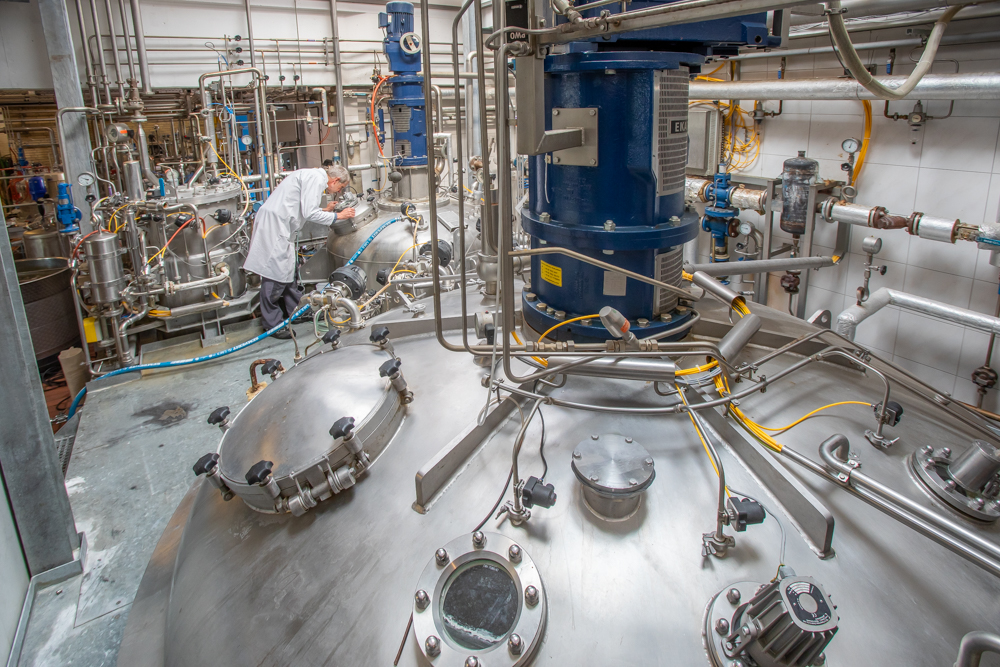

In order to continue to serve our partners and customers smoothly in the future and to ensure a seamless supply, we are currently investing in modern production facilities and expanded storage capacities. We look forward continuing our support to mushroom growers around the world as a competent partner with scientific expertise.

The nematodes are produced in large bioreactors and packaged for worldwide shipping after harvest.

Pictures: k-film, Michael Kottmeier

Contact person for public relations:

Karen Duncker - This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel. +49 (0)4307 -8295-156

e-nema GmbH

Klausdorfer Strasse 28-36

D – 24223 Schwentinental

Tel. +49 (0)4307-8295-0

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.e-nema.de

After recognising a gap in consumers’ knowledge, the Costa Group looked to its packaging to help educate people on ways to use and how to cook mushrooms. Kim Berry looks at what’s in the box. This article was first published in Food & Drink Business May 2021.

Costa marketing and innovation manager – mushroom category Elisa Siliato says there are five types of mushroom buyers and only one of those loves them and buys them every week.

“There are those who don’t use them unless a recipe calls for them, people who don’t really know what to do with them or don’t know the difference between varieties, and then those who know they are good for you but don’t know why. We knew we had to educate people,” Siliato says. The result was Mush-Boom, a consumer-facing advocacy brand using packaging as the main player. “We gave mushrooms a voice, personality, vibrancy and appeal,” she says.

The result was Mush-Boom, a consumer-facing advocacy brand using packaging as the main player. “We gave mushrooms a voice, personality, vibrancy and appeal,” she says.

The first step was to promote the nutritional benefits on the packaging. A QR code lets consumers find out more about its nutrients as well as how they are grown and recipes to try.

On the packaging is the variety’s name, Costa’s quirky descriptive name, and the best occasion to use that mushroom type.

Please read the full article here.

Source: Food & Drink Business

A lot of farms are afraid that water directly on mushrooms will damage the quality but I disagree with that. Of course it depends on the amounts of water you use and the moment of watering, those details are very important but if managed well the water on the mushrooms will give them a smooth cap and some extra weight. What we need to keep in mind is that the moment of watering is very important. Wait for watering on the 1st flush until you see compost activity. If there is no rise in compost temperature wait with water until there is. Normally you see the activity starting on the first picking day when you pick about 0.5 to 1 kg/m2. I always like to water on that first picking day, where the compost just starts to get activity, and let the mushrooms dry naturally, with no force of the fan but with fresh air. What happens is that when you run higher fan speeds after the watering, the fresh air damper will close. You can put a drying program where you lower the CO2 a bit but still the higher fan speed will not increase the amount of fresh air that is needed to dry the mushrooms.

Instead dry the mushrooms naturally and without too much help from the fan speed. Speeding up the fan a lot is not sufficient and is actually working the other way around. When the room is watered the RH is high so the climate system will automatically start drying the room. Leave the fan speed the same so some extra fresh air will come in to do the drying process. Make sure to remove all the access water from the floor directly after watering, if not the process will dry the floor first and the mushrooms will stay wet longer. Make sure you watch your outside conditions to guide this process, with very high humilities you have to use a drying program or consider not too water.

Filling and picking organisation.

If you look at this in a glance one might say: the filling has not that much to do with picking. But it is more relevant than many people think. Before the start of picking a first flush, the picking manager makes a plan. When is the room starting? Do I have to pick clusters or pre-runners? How many pickers do I need in this room during lets say 5 days of picking? And an important one, what is the activity of the room? This I need to interact on the growing from day 2 of picking. And this is where the filling of the room comes into the story.

Before the start of picking the picking manager and the grower have a talk about this room. This should start from the moment pins grow out, so about 4 days before the start of picking that room. The picking manager has knowledge about the expected sales that week, the desired size of the mushrooms and the number of pickers available. The grower has knowledge of the room regarding the activity of the compost, the strain and the number of pins developing. An even room is easy to evaluate but if the filling was uneven or two different types of compost were used, than the story gets a bit more difficult. The growing room will develop uneven and one side might start earlier. One side might give more mushrooms and this means that the picking is not the same on all shelves. And with the tendency to build bigger rooms, more trucks of compost are filled in a room. And every truckload of compost can be a bit different. Sometimes in structure, sometimes in moisture content and even in quantity. And every time the operator of the combine filling machine has the desire to change the settings on the machine. Often his order is to get the compost filled. All shelves full and no compost returning to the compost yard or no compost dumped. But by changing the settings the temperature development of the compost will change too. 2 cm deeper fill can result in a difference of a day for the flush to start. It will also have an effect on the number of mushrooms growing out. And during the flush one side will grow faster than the other.

So the general instruction at filling should be not to make any changes. Better a bit of compost left over or a part of the shelves not being filled. An even better way is to fill out of two trucks in one go with a cross conveyor. That way the compost out of two trucks is mixed and differences are ruled out. Another method is to do a mixed fill of the truck at the compost yard. So fill a layer, fill another layer in another truck and then let the trucks circulate. Of course the best possible way is to do the mixed filling of the truck, together with the combined unloading at filling. The growing will be a lot easier then. The grower has a better chance to produce the number of mushrooms required and the picking can be a lot more accurate.