Mushroom Matter

Welcome on our platform. Why MUSHROOM MATTER? Because mushrooms play an important role in our lives as well in business. Our goal is to bring the world the very latest mushroom news with the upmost care to support the positioning of our beloved Mushroom.

ChampFood International is located in Vierlingsbeek, North Brabant. They produce ChampFood, a natural and organic mushroom supplement, which is available worldwide.

Their company was founded in 1990 by Toon Donkers and Jan Baltussen and has since then been active as producer, supplier, and distributor of ChampFood supplementary food for the mushroom industry.

From the start, the founders worked on higher productivity - and therefore bio-efficiency - of the fully grown compost, by developing an improved type of supplement.

In addition they developed a specific treatment that ensured that the added proteins were released even more equally during the flushes.

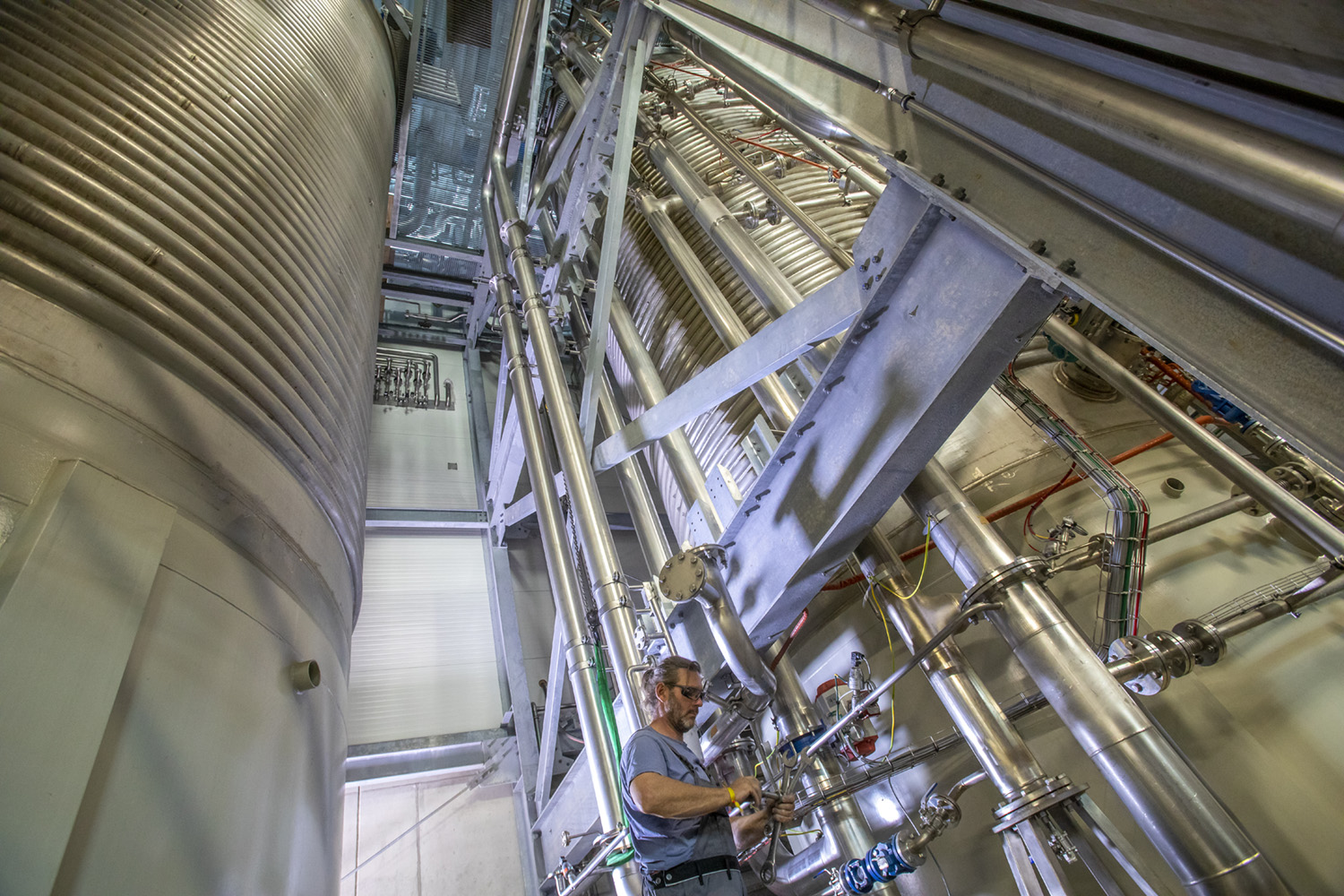

In 2008 the company moved to its current production location, enabling further growth and innovation. In addition, the team was reinforced with the arrival of Eric Vernooij, who has enriched the sales team with his knowledge of mushroom cultivation.

Technological development

Through the continuous use of the latest technology in terms of absorption requirements and based on in-depth nutritional and practical knowledge of composting and cultivation, ChampFood has become a market leader with a leading product; ChampFood now supplies a wide variety of products for supplementing the cultivation of white and brown mushrooms and other mushroom exotic species all over the world.

An important part of their success is the good relationship with their customers. Intensive cooperation with their customers enables them to adapt customised supplement compositions to the type of compost/recipe. Their customers let them know that they appreciate that flexibility. As a result, they have developed a large number of customized recipes for their customers over the years.

Challenge

A rapidly growing world population that demands more food is a difficult issue. Because the mushroom sector is relatively flexible and can therefore respond well to these problems, ChampFood sees many developments in mushroom cultivation. Fortunately, a lot of knowledge is shared within the mushroom industry, often originating from Dutch roots.

The production of mushrooms is possible with raw materials such as straw, horse, and chicken manure and the harvest can take place both manually and mechanically. Innovative hand harvesting systems are increasing, although they require high investments. The costs of raw materials and energy are also increasing. It is therefore important that the harvest produces enough to compensate for investments and costs.

The importance of efficiency

In the future, the viability of a production company will no longer be determined solely by the maximum number of kilos of mushrooms per m2, but also by keeping the costs per cultivation area as low as possible, so that the highest possible return can be generated. This requires the highest possible bio-efficiency of the substrate. Supplementing the substrate will therefore become even more essential. It now appears that the worldwide production of mushrooms is 15% to 20% higher when using a supplementary substrate. ChampFood is convinced that supplementation will therefore play an even more significant role, especially since the cost of supplement is less than 5% of the total costs per m2 of cultivation area (not even taking into account energy and labor costs). This makes the application of supplements a very healthy and solid investment.

ChampFood would like to welcome you during the Mushroom Days at their stand number 53.

Visit the Champignondagen on 10, 11 and 12 May 2023

The International trade fair 'De Champignondagen' will take place again on 10, 11 and 12 May 2023. This fair is organized in Brabanthallen 's-Hertogenbosch, the Netherlands.

The Dutch Mushroom Days is the largest and most spectacular international trade fair for the edible mushroom industry worldwide, usually with around 100 exhibitors and 3000 visitors from 80 countries. The last – successful – edition was in 2019.

On the website you will find all the necessary information and we will keep you informed of all the latest developments.

image: Wikimedia Commons

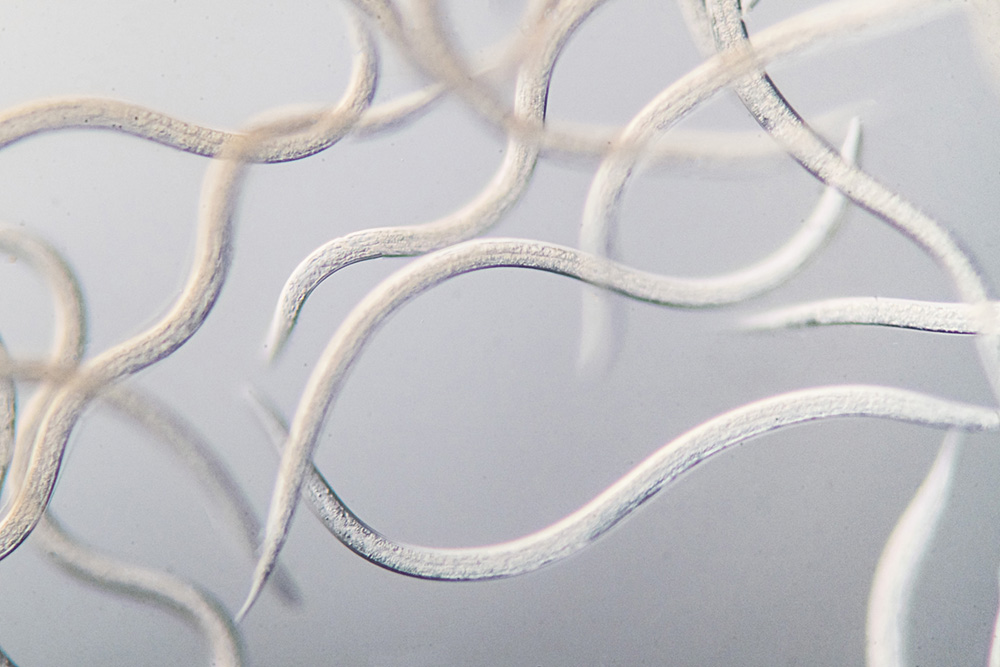

Researchers from The University of Queensland have discovered the active compound from an edible mushroom that boosts nerve growth and enhances memory.

Professor Frederic Meunier from the Queensland Brain Institute said the team had identified new active compounds from the mushroom, Hericium erinaceus.

“Extracts from these so-called ‘lion’s mane’ mushrooms have been used in traditional medicine in Asian countries for centuries, but we wanted to scientifically determine their potential effect on brain cells,” Professor Meunier said.

“Pre-clinical testing found the lion’s mane mushroom had a significant impact on the growth of brain cells and improving memory.

“Laboratory tests measured the neurotrophic effects of compounds isolated from Hericium erinaceus on cultured brain cells, and surprisingly we found that the active compounds promote neuron projections, extending and connecting to other neurons.

“Using super-resolution microscopy, we found the mushroom extract and its active components largely increase the size of growth cones, which are particularly important for brain cells to sense their environment and establish new connections with other neurons in the brain.”

Co-author, UQ’s Dr Ramon Martinez-Marmol said the discovery had applications that could treat and protect against neurodegenerative cognitive disorders such as Alzheimer’s disease.

“Our idea was to identify bioactive compounds from natural sources that could reach the brain and regulate the growth of neurons, resulting in improved memory formation,” Dr Martinez-Marmol said.

Dr Dae Hee Lee from CNGBio Co, which has supported and collaborated on the research project, said the properties of lion’s mane mushrooms had been used to treat ailments and maintain health in traditional Chinese medicine since antiquity.

“This important research is unravelling the molecular mechanism of lion’s mane mushroom compounds and their effects on brain function, particularly memory,” Dr Lee said.

The study was published in the Journal of Neurochemistry.

UQ acknowledges the collaborative efforts of researchers from the Republic of Korea’s Gachon University and Chungbuk National University.

Source: The university of Queensland

Credits: Queensland Brain Institute

Libre's mycelium bacon alternative is supposedly 70% less fatty, 52% less calorific than actual pork.

Libre founder Alan Ramos became intrigued by sustainable meat alternatives during a spell travelling the Far East.

Taking a graduation sabbatical in China and Taiwan, where he no doubt chewed over differences in cuisine, Ramos began his own vegan journey after becoming engaged with the need to tackle climate change and the role of industrial-scale meat production.

Five years later, Ramos, a US native born to Mexican parents, was at work in Barcelona hatching his startup concept.

With his startup Libre Foods, Ramos has opted for mushroom textures and tastes, drawing on mycelium compounds found at the vegetable's root, to serve up vegan alternatives to bacon, steak and chicken.

The first of the products, Libre Bacon, is advertised as containing 70% less fat, and 52% less calories than actual pork products. Libre's steak and chicken alternatives are still in development. But bacon is the priority; Libre believes 32.5 kg of pork is consumed by the average European consumer each year.

Mushrooms are said to offer advantages in meat-free production because they grow 365 days a year in European climates, in all weather conditions.

And Libre is banking on its formula as a winner for Western taste palettes; early trials at vegan foodie events in LA and Berlin were apparently "very well received". It's claiming to be first in the category as well — until now there hasn't been a mushroom-derived bacon product, at least within EU borders.

e-nema GmbH celebrates 25 years

In 1997, Prof. Dr. Ralf-Udo Ehlers, Dr. Arne Peters, and Tillmann Frank started their joint mission to produce entomopathogenic nematodes for biological pest control on large-scale. What started as a spin-off of a university research project has grown into an internationally successful company with over 70 employees. The three partners share the vision of sustainably reducing the global use of chemical pesticides by providing biological alternatives. To achieve this, it is necessary to offer biological products in large quantities and at competitive prices. For this reason, e-nema GmbH has always invested many resources in research and the expansion of production capacities and has meanwhile risen to become the largest producer of entomopathogenic nematodes worldwide.

To celebrate its 25th anniversary, e-nema has modernized its brand identity and corporate website. An important step to communicate the dynamic growth and the expertise gained over the years in the field of biological crop protection in an appealing way to the outside world.

Sales Manager and mushroom expert Ulrich Tiemann is optimistic about the future after a year of difficult general conditions:

"We have already achieved a lot in the past years, but the road towards sustainable agriculture and food production is still very long. The mushroom market is an absolute positive example for us. Through the intelligent use of resources and the use of nematodes to control sciarids and phorids, many people are already being supplied with healthy, high-quality, and sustainable mushroom products. And we are very proud to play our part in this. We assume that awareness will also change more and more in many other plant cultures in the future, or that the change is already in full swing."

Visit the e-nema website here

www.e-nema.com

Mush Comb visited their dealer in America

Last month Mush Comb visited the dealer in America to review the strategies for the coming years.

Mushroom supply & services (MSS Inc) has a long history in North America. David Iaconi Sr has been a grower for many years and later opened his business in providing unique, quality growing products and equipment to the mushroom farmer.

Starting with only 1 product, MSS Inc. has grown and expanded into offering a multitude of mushroom supplies, equipment, and consulting services. Mushroom Supply & Services is dedicated to problem-solving. Their commitment is to work with the growers and match their products with operational needs.

You will always get friendly service from David Sr, David Jr, and Liza. A great team that you can rely on.

Button Mushrooms vs. Shiitake Mushrooms

Button mushrooms and shiitake mushrooms are two of the most popular types of mushrooms, and ones that you can easily find at a grocery store or in a list of ingredients for tasty pasta dishes or soups. However, knowing which species to use can be confusing. Many people are not familiar with the differences in how mushrooms are cultivated and do not know how to identify their different flavors. When should you use a button mushroom? If you don’t like the taste of a shiitake, should you assume that you will not enjoy a button mushroom either?

Though button mushrooms and shiitake mushrooms are two of the most well-known and widespread species, if you can’t tell them apart, you are not alone! This article compares and contrasts the appearance, history, taste, and uses of each. By the end, you will know how to identify each and understand some of their major similarities and differences. Let’s learn about these two mushrooms now!

Source: A to Z Animals

I am losing my quality

Imagine the third picking day of a first flush. In the morning the pickers are picking a beautiful mushroom.

Around noon the mushrooms are starting to lose colour and 3 hours later they start growing like mad. Stems are stretching and caps are getting soft.