Mushroom Matter

Welcome on our platform. Why MUSHROOM MATTER? Because mushrooms play an important role in our lives as well in business. Our goal is to bring the world the very latest mushroom news with the upmost care to support the positioning of our beloved Mushroom.

A new automatic picking lorrie was developed by Mush Comb with the focus on being absolutely picker friendly. Being friendly in use but for example also in maintenance. Each user confirms that the picking lorrie is remarkable easy made so no worries about for example hydraulic hoses breaking.

This started three years ago with Jasper Kanters from Kanters Paddestoelen. According to Jasper so far there was no picking lorries on the market which was friendly to work with. The practical growing and harvesting experience from a Dutch grower like Kanters was combined with the technology minded people from Mush Comb. A testing phase started which in the summer of 2017 resulted in 16 new automatic picking lorries.

It was the start of a new choice in picking lorries. First focus has been on automatic up/down picking lorries because growers saw most advantages in this function and often automatic forward/backward was not being used so why bother this extra investment.

In 2019 the product range was still expanded with full automatic up/down and driving to meet the requirements of each potential grower.

According to Bob Holtermans not only the high picking efficiency, high safety standard, practical use and low maintenance are the reason for the high demand of these picking lorries. It is in combination with the flexibility of Mush Comb. Because although the automatic picking lorries are made from the same basic principle each mushroom grower gets their own unique picking lorries. Customers have the possibility to consult with the engineers of Mush Comb with regard to packaging sizes, door spaces, etc. This to create the optimal working tool when it comes to assisting in the harvest.

The proof is given by all the growers which were convinced and have bought this new harvesting tool. Growers like:

- Kanters Paddestoelen, Netherlands

- Pleunis Mushrooms, Belgium

- Jacobs Champignons, Netherlands

- Peeters-Luyten, Netherlands

- Lesage Champignons, Belgium

- Van Nieuwenhoven-Steijvers, Netherlands

- Vandechamp, Belgium

- Agarica, Netherlands

- Champignonkwekerij Dingemans, Netherlands

- AK Champignons, Netherlands

Meaning the top of the manual harvesting industry in Netherlands and Belgium are convinced. This part of the world is still seen as great example for the rest of the world. Reason enough for growers worldwide to step in the footsteps of these great Dutch and Belgium mushroom growers.

Contact info from Mush Comb can be found on www.mushcomb.com

Fungi That 'Eat' Radiation Are Growing on the Walls of Chernobyl's Ruined Nuclear Reactor

Jan 08,

2026

Back in 1991, scientists were amazed when they made the discovery...

In the eerie environment inside the abandoned Chernobyl Nuclear Power Plant, researchers remotely piloting robots spotted pitch black fungi growing on the walls of the decimated No. 4 nuclear reactor and even apparently breaking down radioactive graphite from the core itself. What's more, the fungi seemed to be growing towards sources of radiation, as if the microbes were attracted to them!

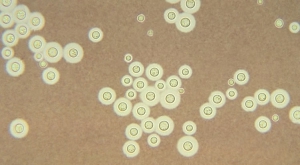

More than a decade later, University of Saskatchewan Professor Ekaterina Dadachova (then at the Albert Einstein College of Medicine in New York) and her colleagues acquired some of the fungi and found that they grew faster in the presence of radiation compared to other fungi. The three species tested, Cladosporium sphaerospermum, Cryptococcus neoformans and Wangiella dermatitidis, all had large amounts of the pigment melanin, which is found – among many places – in the skin of humans. People with a darker skin tone have much more of it. Melanin is known to absorb light and dissipate ultraviolet radiation, but in the fungi, it seemed to also be absorbing radiation and converting it into chemical energy for growth, perhaps in a similar fashion to how plants utilize the green pigment chlorophyll to attain energy from photosynthesis.

Back in 1991, scientists were amazed when they made the discovery...

In the eerie environment inside the abandoned Chernobyl Nuclear Power Plant, researchers remotely piloting robots spotted pitch black fungi growing on the walls of the decimated No. 4 nuclear reactor and even apparently breaking down radioactive graphite from the core itself. What's more, the fungi seemed to be growing towards sources of radiation, as if the microbes were attracted to them!

More than a decade later, University of Saskatchewan Professor Ekaterina Dadachova (then at the Albert Einstein College of Medicine in New York) and her colleagues acquired some of the fungi and found that they grew faster in the presence of radiation compared to other fungi. The three species tested, Cladosporium sphaerospermum, Cryptococcus neoformans and Wangiella dermatitidis, all had large amounts of the pigment melanin, which is found – among many places – in the skin of humans. People with a darker skin tone have much more of it. Melanin is known to absorb light and dissipate ultraviolet radiation, but in the fungi, it seemed to also be absorbing radiation and converting it into chemical energy for growth, perhaps in a similar fashion to how plants utilize the green pigment chlorophyll to attain energy from photosynthesis.

Click here for the full article

Source: RealClear Science By Ross Pomeroy - RCP Staff

Belgian Scientists have discovered the remains of the oldest mushroom in a collection piece from the Africa Museum in Tervuren.

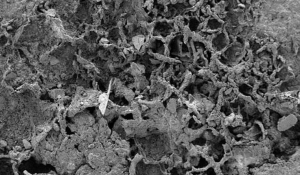

The fossilised remains – 715 to 810 million years old – were found in a rock in the collection by scientists from the French-speaking university ULB.

This research casts new light on when mushrooms first became present on earth, as previous findings had placed the oldest mushroom at ‘only’ 460 million years old.

The fossil, however, does not look at all like a mushroom, more resembling the roots of a plant or tree, according to reports. The results suggest that fungi helped create the first plants on Earth 500 million years ago.

“This is an important discovery, which invites us to review the chronology of the evolution of organisms on earth,” concludes research leader Steeve Bonneville, who published his study in the scientific magazine Science Advances.

There may be still many older mushrooms, as scientists have only discovered about 120,000 species of an estimated 3.8 million.

Source: Jules Johnston of The Brussels Times

Photo: ULB

Filling the growing room

Jan 08,

2026

How mushrooms grow and the yields are determined at filling. Assessing the compost and casing soil determines the final quality of the mushrooms. After this assessment, the settings are made on the filling machine. Any mistakes made at filling, will haunt you for the rest of the cropping cycle. On larger farms “growers" focus increasingly less on filling. Just a quick look at the compost and casing soil at the start, set the machine… and that's about it.

Why is filling so important?

Compost quality

Compost quality is influenced by: colour, texture, smell, temperature, hard or soft structure. How much water can the compost absorb and should you water at filling? How well will the CAC material grow? Only paying attention during the first 15 minutes of filling is not enough to get these details right. The least you can do as a grower is to be physically present three or four times at filling, to check the compost, casing soil and the filling quality. And have a chat with the filling machine operator.

The operator also has to be almost a grower; not only with an understanding of the machine, but also understanding what compost and casing soil quality is and how to handle the raw materials correctly. And not what I keep on seeing more often: filling the growing room with compost and casing as quickly as possible and not paying enough attention to the actual filling process. Sometimes the result is a whole groove along the bed because, for example, there was a piece of wood lodged in the CAC axle. There won't be any mushrooms growing there....

The operator should therefore ALWAYS stand by the filling machine and watch the machine where the compost with casing enters the growing room. The operator should look at the CAC and levelling axles. From this position, you can see what you are doing and stop the machine immediately if anything goes wrong.

Filling is the foundation of further growth. It's not simply completing a task, but also thinking about the quality of compost and casing you are dealing with and how it should be handled during filling and afterwards during growing.

Master class

The next masterclass course will be organised from 9 – 14 March 2020. This course is fully booked!

NEW: Live Training Mushroom Signals Essentials

Mushroom Signals Essentials live training will be organised from 8-12 June 2020.

Live training combined with e-learning. E-learning offers the basics, leaving more time for individual questions and farm walks during live training!

Read more by click on this link

Mark den Ouden

A good stagger to meet targets

Jan 08,

2026

The targets for a mushroom farm are amongst others:

• Meet market requirements

• Good quality at the lowest possible harvesting costs

To meet the market requirements the farm needs about the same amount of mushrooms every day, seven days per week. Maybe a bit more on one day than the other depending on sales. This means generally picking seven days per week.

In most of the countries picking in the weekend is expensive so the target is often to avoid that when possible, or have mushrooms which are easy to pick. To have a relatively low cost price for picking it also helps to have more or less the same amount of mushrooms per day. So the planning of the picking and the calculation of the number is pickers needed is easier. To achieve all this a good stagger of the mushrooms is an absolute must. This starts with the choice of casing soil and the way the casing is treated.

A fine structured and perfectly finished layer of casing results often in too many mushrooms and a picking period of only 3 to 4 days in the first flush. So choosing a rough casing with an open finish of the surface helps in staggering the first flush.

Then the next important tool is the fructification or pinning. Take time to cool down the room. Take CO2 and room temperature down gradually over a period of at least 11 days. In the beginning the room temperature can be kept around 20° C for about 2 to 3 days. The compost will follow after a few days anyway.

Build in steps that are the same every day and keep humidity at the setpoint required. 95% for the first 4 days of fructification and from there a drop of 1% per day. Make sure that the band is set narrow on the RH because a deviation of just 2% can cost you the staggering you need so badly. So by taking time in this period, time and money can be saved during the picking again.

Just remember, the more un-even it looks the better. And do not look for too many mushrooms.

Avondale, PA — Mushroom growers are entering 2020 with record sales volumes, increasing retail prices and solid demand for fresh mushrooms, according to the American Mushroom Institute.

The September shipment report from the Mushroom Council™ shows domestic mushroom production set a new all-time high. This was the fourth consecutive new monthly high and reflects steady sales growth throughout the summer months. Both June and August volume exceeded 80 million pounds for the first time ever, indicating that mushroom sales are strong year-round. Combined shipments (domestic plus imports) also hit new record highs.

Mark Lang, MBA, Ph.D., University of Tampa, analyzed the recent data trends for the Council. “As mushrooms become a staple item for many Americans and more people start consuming them, demand has risen steadily for the past decade,” said Lang.

Retail prices are also seeing a steady increase. The most recent tracking data from IRI showed that as of Nov. 3, 2019, the average selling price for fresh mushrooms increased from $4.06/lb in October 2018 to $4.17/lb in October 2019, with an average increase of 1% per month.

“Retailers and their shoppers are demonstrating that the demand for fresh mushrooms is no fad—it’s a long-term trend. We see expanding displays and more real estate in the produce department, combined with record high retail prices—all the result of consumers demanding more healthy, flavorful plant-forward foods. Fresh mushrooms are well positioned for even greater growth in the near future,” said Steven Muro, President, Fusion Marketing.

Click here to read the full article

Source: American Mushroom Institute

NASA building homes made of fungi for Moon, Mars

Jan 08,

2026

Instead of habitats made of metal and glass, NASA is exploring technologies that could grow structures out of fungi to become our future homes in the stars, and perhaps lead to more sustainable ways of living on Earth as well.

Creating a livable home for future astronauts means doing more than growing a roof to go over their heads.

Astronauts will need to have all their basic needs met, just like on Earth, and face the additional challenges of living in a harsh environment on a distant world, the US space agency said in a statement.

Keeping that in mind, the myco-architecture project out of NASA’s Ames Research Center in California is prototyping technologies that could “grow” habitats on the Moon, Mars and beyond out of life – specifically, fungi and the unseen underground threads that make up the main part of the fungus, known as mycelia.

“Right now, traditional habitat designs for Mars are like a turtle – carrying our homes with us on our backs – a reliable plan, but with huge energy costs,” said Lynn Rothschild, the principal investigator on the early-stage project.

“Instead, we can harness mycelia (vegetative part of a fungus) to grow these habitats ourselves when we get there”.

Click here for the full article

The future of meat substitutes may not involve plants. While food manufacturers race to bring new soy, wheat and pea-based products to market, a handful of start-ups have been hard at work developing a new kind of meat alternative from fungi.

Two companies in the emerging space are gearing up to launch their first products this year. Emergy Foods, Boulder, Colo., is working with culinary experts to perfect its steak alternative, which will debut in restaurants in Colorado under the newly unveiled Meati brand.

Berkeley Calif.-based Prime Roots, formerly Terramino Foods, also plans to launch its first products in 2020. The company uses Koji, a Japanese fungus traditionally used to make soy sauce and sake, to create several kinds of seafood, including salmon burgers, shrimp, lobster and tuna as well as chicken, sausage and beef.

Fungi has several advantages over conventional plant-based proteins, the start-ups said. Its fibrous texture enables a wider variety of types and cuts of meat. The flavor is neutral, eliminating the need for masking agents. It requires only a small amount of land, energy and water to produce, and it packs a nutritional punch that matches meat and rivals plants.

Read the full article to see how it's made!