Latest newsletter

Stay connected,discover the latest in the mushroom industry

Our newsletters bring the world of mushrooms straight to your inbox, from the latest innovations and technologies to inspiring stories and sustainable solutions. Every month, thousands of readers, growers, suppliers, researchers, and enthusiasts from across the globe, stay informed through Mushroom Matter.

Not yet subscribed?

Stay ahead of the curve and never miss an update on trends, insights, and stories from the mushroom world.

Share your story, innovation or brand

Would you like to position your company, product, or research in front of an international audience?

Our platform offers global visibility through::

-

Monthly newsletters reaching professionals across the mushroom value chain

-

Sponsored articles and advertorials that highlight your expertise

-

News placements about your company’s latest developments or innovations

-

Website banners and packages tailored to your goals

Advertising with Mushroom Matter means being part of a community that values quality, innovation, and connection within the global mushroom industry.

Together we make the mushroom world grow and matter

At Mushroom Matter, we believe in sharing knowledge, inspiring innovation, and connecting people who care about the future of fungi. Whether you want to read, share, or advertise, this is your gateway to a growing global network.

The mushroom sector is entering a transformative phase, where farming tradition meets cutting-edge innovation. Once seen simply as a niche crop, mushrooms are now emerging as powerful contributors to sustainable agriculture, human wellness, and even material science.

Shaping a circular food system

One of mushrooms’ greatest strengths lies in their resource efficiency. Unlike many crops, they flourish on byproducts such as straw, sawdust, or coffee grounds, making them natural allies in the shift toward circular farming. For growers, this opens opportunities to reduce waste, diversify substrates, and partner with other agricultural industries to create closed-loop systems.

Health on the rise

Consumer interest in functional and nutrient-rich foods continues to surge, and mushrooms are at the forefront. Varieties like Lion’s Mane and Reishi are valued for their adaptogenic potential, while everyday favorites such as oyster and button mushrooms are being recognized for their protein, fiber, and vitamin D. This dual reputation, both as staple food and functional ingredient, is fueling new product development across the food and supplement industries.

Farming smarter with technology

The drive toward efficiency and scalability has accelerated adoption of digital tools. Automated climate systems, AI-based monitoring, and sensor-driven data analytics are helping growers fine-tune production while tackling labor shortages. Farms that embrace these technologies are finding new ways to improve yields, cut costs, and meet rising demand with consistency.

Beyond the plate

Mushrooms are increasingly breaking into non-food markets. Mycelium, the root-like structure of fungi, is now being used to create biodegradable packaging, sustainable textiles, and even construction materials. These developments highlight the mushroom industry’s potential to play a role far beyond food, positioning it as a cornerstone of sustainable innovation.

Building a future-ready industry

As mushrooms gain attention worldwide, the industry faces both opportunity and responsibility. Growth must balance innovation with sustainability, ensuring practices that protect natural resources while meeting expanding consumer expectations. Collaboration between farmers, researchers, and entrepreneurs will be vital in keeping the sector resilient.

Mushrooms today are not only a crop but a vision of what agriculture and innovation can achieve together. For farmers and industry leaders, the message is clear: cultivating mushrooms means cultivating the future.

In the following weeks we'll dive deeper into theses subjects. Do you have expertise, research or success stories on these subjects that can inspire others? Reach out and let’s share your voice with our readers!

Published by Mushroom Matter: connecting the global mushroom community through insight, innovation, and inspiration

When you think of mushrooms, you might picture them on your plate. But researchers in Spain are showing how fungi can also shape the future of packaging. Their latest project turns mushroom mycelium into a biodegradable, durable material that can replace plastic.

This is part of a growing global movement: companies in the US, Europe, and Asia are all exploring how fungi can tackle one of the world’s biggest waste challenges. By transforming side streams and agricultural by-products into packaging, mycelium offers a double win, reducing plastic pollution and making better use of resources.

For mushroom growers and industry players, it’s another example of how fungi are stepping outside the farm and into mainstream innovation.

by Mushroom Matter

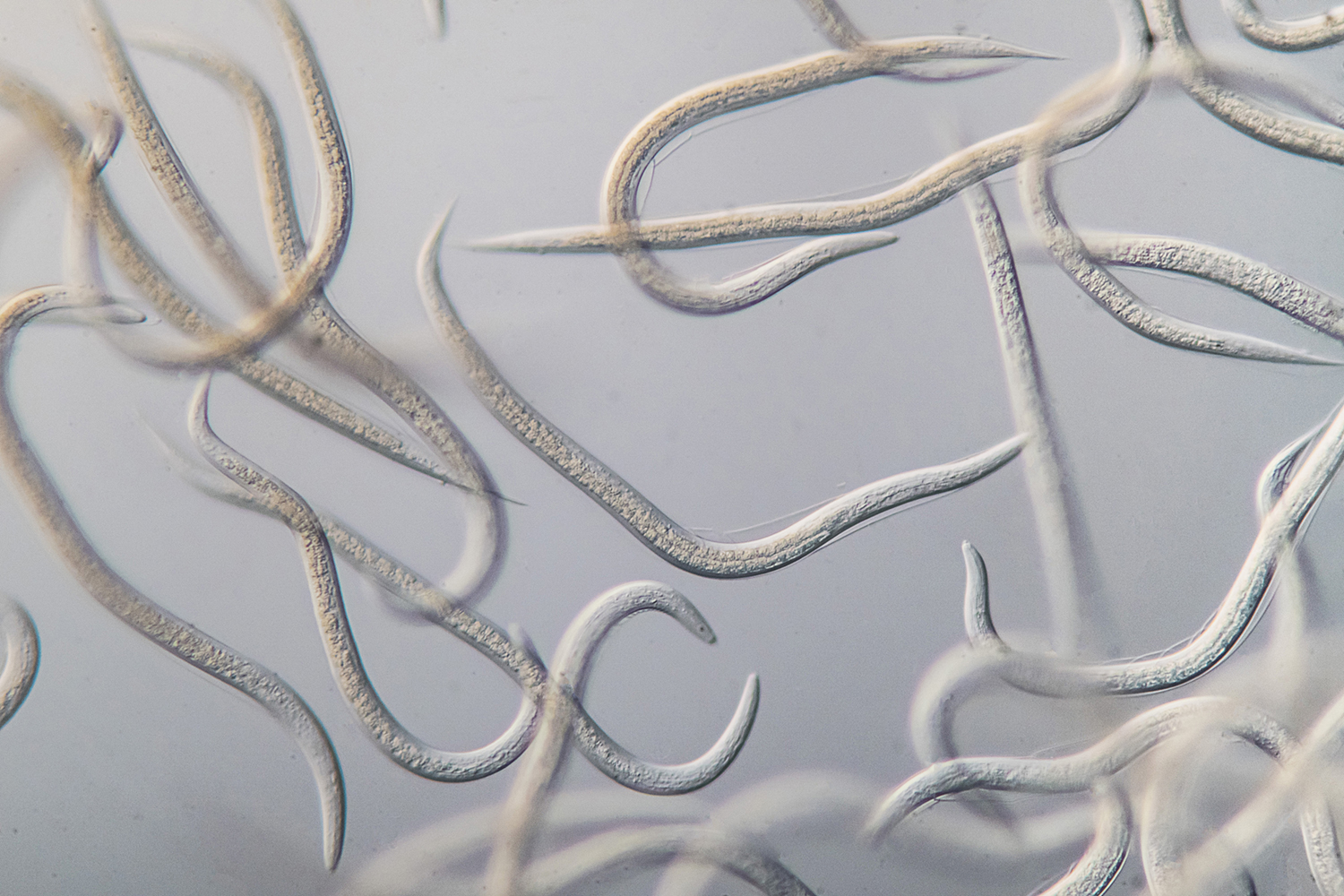

e-nema develops new innovative nematode formulation

For over 25 years, the company e-nema from Schwentinental in northern Germany has been producing entomopathogenic nematodes for biological plant protection.

So that the nematodes can be transported to users all over the world, they have to be mixed with a carrier material. e-nema currently offers its nematode products in three different formulations.

e-nema predominantly uses diatomaceous earth in the formulation. This is a naturally occurring powder made from the shells of fossilised diatoms, which binds water and is well suited as a carrier medium for nematodes. One disadvantage of diatomaceous earth, however, is that optical residues can remain on the leaves of the treated plants. These are absolutely harmless, but are a disadvantage for ornamental plant cultivation and some other plant cultures.

The previous solution was a gel formulation based on polyacrylate. The tiny synthetic polymers can bind a lot of water and make it an excellent carrier material for nematodes. The disadvantage of this formulation is that parts of these small polymers remain in the soil. This prompted e-nema to look for a new formulation that is both organic and leaves no residue on plants or in the soil.

After intensive research and various approaches, e-nema is proud to present its new Ecophyll formulation. Ecophyll is made from 100% organic and renewable resources and leaves no residue. Ecophyll dissolves very well in water and can be shipped with less packaging material. Ecophyll will be available in the product nemaflor® F from now on. In parallel, extensive tests are being carried out in the field to evaluate the performance of Ecophyll in other products and crops.

„Our aim is to maximise the positive effects of our products along the entire value chain. This starts with the resources used to produce the nematodes and ends with the plants on which they are applied. With our Ecophyll formulation, we have taken a further step towards plant protection in harmony with nature.“ - Tillmann Frank, CEO e-nema GmbH.

Source: e-nema

The Growtime company has been steadily increasing exports and securing the confidence of major agricultural enterprises worldwide.

How GROWTIME and Osatina Grupa came together: a leap of faith that paid off

GROWTIME has again signed a contract with Osatina Grupa, a leading agricultural company in Croatia, for the supply of Newton mushroom picking lorries. Osatina Grupa, headquartered in the beautiful Đakovština area, is renowned for its comprehensive agricultural operations, including fruit and vegetable farming, dairy and meat production, animal feed production, and the generation of bioenergy. Their diversified and synergistic business model, which has been perfected over more than 25 years, emphasizes sustainability and modern technology.

The story of our collaboration with Osatina Grupa is one of risk, trust, and long-term success. As a large and innovative corporation, Osatina Grupa was a highly sought after business partner. They had numerous offers, many of which were less costly than what GROWTIME could provide. Negotiations during the COVID-19 pandemic added to the challenge, as physical presentations of our products were limited and travel was impossible due to the restrictions imposed.

Despite these hurdles, our high-quality and efficient products and the promise of lower overhead in the long run convinced Osatina Grupa to choose GROWTIME. They decided to take a risk on our more expensive Newton mushroom picking trolleys, driven by the argument that these high-quality devices would be more cost-effective over time.

A decision proven right

The initial cost of our trolleys appeared higher, but the investment was projected to pay off through superior performance and reliability. Osatina Grupa’s faith in our products was validated when they returned to GROWTIME for more of the same Newton picking trolleys a few years later, proving the wisdom of their original decision. This repeat business speaks volumes about the quality of our offering.

For GROWTIME, a client returning for the same product is the highest form of endorsement. It underscores that the initial investment, despite the higher initial price, was justified by the long-term benefits. The repeated orders from Osatina Grupa confirm the value and effectiveness of our solutions, showcasing our dedication to developing products that align perfectly with customer demands.

Cutting-edge Newton as well Pascal trolleys drive GROWTIME’s global success

A key driver behind this international success is GROWTIME's innovative products such as Newton & Pascal mushroom picking trolley. Known for their exceptional quality and cost-effectiveness, the Newton and Pascal trolleys has quickly become a favorite among large-scale mushroom producers. It was Osatina Grupa’s top choice then, and it’s their top choice now.

The trolleys feature from Growtime a robust design and user-friendly functionality, including electric drives and winches that automate the movement of the platform. This not only improves the ergonomics of the work but also increases the yield by allowing more precise and efficient picking. Additionally, the trolleys are equipped with advanced safety features and easy-to-use controls, ensuring both high performance and worker safety.

Moreover, Newton as well Pascal lorries ensure a quick return on investment due to their aforementioned low maintenance costs and high effectiveness. This combination of reliability and efficiency has made them a preferred option for agricultural enterprises looking to optimize operations and reduce overhead. For more information about the Newton mushroom picking trolleys and to explore GROWTIME's full range of products, visit this link.

EuroMycel launches new website

EuroMycel is excited to announce the launch of their brand new website! Browse through for detailed information on their history, philosophy, and Mycelium varieties. Discover their production process, product creation, and meet their team. Today you get a sneak peek into EuroMycel’s journey.

Story of EuroMycel

Established in 1868, Royal Champignon pioneered the Loire Valley's mushroom industry. After merging with Guilbaud Group, EuroMycel, once a Guilbaud Group subsidiary and now part of France Champignon, became a key historical spawn maker.

The group has grown since the 1950s through external expansion, allowing for innovation capacity in product development to distribution. EuroMycel has acquired impressive expertise and a unique strain collection, which has resulted in a distinctive "savoir-faire."

Philosophy

EuroMycel believes that genetics of Agaricus bisporus does not limit biotransformation. They use a unique physiological conditioning process on their commercial sub lines to maximize mushroom compost. Their approach is different from standard breeding strategies as their varieties are based on biochemical markers in the vegetative phase.

Mushroom Spawn

The company's unique strain maintenance relies on mycelium interaction with compost to provide reliable spawn products with consistent pinning performances. They have a deep knowledge of fungal physiology and use a specific step-by-step vegetative screening process combined with strict water control to optimize selectivity. They enhance the absorption capacity of the spawn through a sophisticated physical measurement process, critical for the bio-transformation in compost and crop growth. This process also enables strain differentiation.

Discover more about their expertises on https://www.euromycel.com

Contact their team via https://www.euromycel.com/contact

ChampFood International is excited to share some recent developments, including the introduction of Luc Baltussen to their sales team. Luc joined the company on May 1st, bringing with him a wealth of experience in supply and logistics management. He made an impressive start by participating in the mushroom days, where he had the opportunity to meet ChampFood relations and industry colleagues in person. Luc's knowledge and skills have made him a valuable addition to the Sales Support department.

Alongside Luc's arrival, ChampFood has also welcomed four other new members to their team, showcasing their strategic investment in the company's future.

These new team members, all under the age of 30, will contribute their unique perspectives and energy to various departments such as production, finance, office management, and purchasing. ChampFood is pleased with their decision to join their company, as they believe investing in young professionals is vital for sustained success.

This picture shows the new team members:

From left to right top row: Aniek Voesten and Ramon Coenen

From left to right bottom row: Luc Baltussen and Remco Sleutels.

In recent years, ChampFood has experienced the retirement of several employees, with more expected in the coming years. This natural transition has presented them with an opportunity to infuse their workforce with fresh talent. Luc and the four new colleagues will help ensure a seamless transition and contribute to their ongoing growth and innovation. ChampFood recognizes the importance of nurturing the next generation of professionals within the mushroom industry.

For more updates please visit: ttps://www.champfood.com/ or follow the company page on LinkedIn: "champfood international"

The move comes at a time when the horticulture industry looks to accelerate its automation efforts to benefit Canadian growers.

Vineland Research and Innovation Centre (Vineland) has announced the transfer of its patented robotic mushroom harvesting technology to Mycionics, a Canadian agtech company located in Putnam, Ontario.

The move comes at a time when the horticulture industry looks to accelerate its automation efforts to benefit Canadian growers with Vineland uniquely positioned to contribute, given its innovative technology portfolio.

Under the terms of the agreement, Vineland’s intellectual property will be incorporated into Mycionics patent portfolio as they commercialize their mobile robotic harvesting system.

Please read the full article here.

Source: Greenhouse Canada

The purchase brings Ecovative greater global vertical integration as it expands international production of mycelium materials in fashion, packaging, and food.

Ecovative acquires Lambert Europa Spawn and Substrate facility in the Netherlands, expanding global reach for the company's patented mycelium technologies to more than 5 continents.

GREEN ISLAND, N.Y.--(BUSINESS WIRE)--Ecovative, the world's leading mycelium technology company, today announced the purchase of Lambert Spawn Europa B.V., a state-of-the-art mushroom spawn production facility in the Netherlands, from a subsidiary of Pennsylvania-based Lambert Spawn Company. The purchase vertically integrates a major source of mushroom substrate — mixtures of raw agricultural products inoculated with specialized mushroom strains — within the operations of the world's premier developer of mycelium materials and products. The new line of supply will enable and support Ecovative's consistent and rapid expansion internationally and across all categories as both a producer and supplier to other mycelium companies.

Under Ecovative's ownership, the facility will continue producing spawn to serve its list of existing clients, including mushroom growers and producers of mycelium materials. It will also produce proprietary blends of substrate used to grow mycelium materials. These materials support Ecovative's Forager™ and Mushroom™ Packaging divisions, as well as My™Forest Foods and its popular My™Bacon, alongside a growing list of licensee companies. Forager will use the substrate to supply natural mycelium materials for the fashion and apparel industries, such as leather-like hides and high performance foams, and Mushroom Packaging will use the substrate to produce composite materials used to replace plastic foam packaging.

"Ecovative is committed to providing the world's best mycelium technologies," says Eben Bayer, Ecovative's CEO and co-founder. "We're working closely with Lambert and the facility's incredible team of industry professionals to continue providing existing clients with the same quality products they know and love. This acquisition also positions our company to ensure the highest quality of feedstock for a wide range of new mycelium materials, enabling the best possible products and the capacity to supply our quickly growing global network of customers and licensees as they continue to expand over the coming years."

"We are proud of the state-of-the-art facility we built in Venlo, and the team we gathered to operate it," says Scott McIntyre, Executive Vice President and Co-Owner of Lambert Spawn. "Since collaborating with Ecovative, it has become clear that they are the ideal team with the right expertise of stewarding the facility and caring for its customers, while also creating exciting new opportunities as Lambert continues to focus on serving and growing our North American markets. The Lambert name was built on quality and innovation, and we are glad that Ecovative will bring this same commitment to Lambert Spawn Europa, for everyone's continued success."

The Netherlands-based team and facility will continue to produce the same high quality spawn and substrate, servicing existing mushroom growers and new clients, serving markets in Europe, Middle East, Africa, and South America. The facility employs 17 people, and is capable of producing approximately 20 million pounds of spawn and substrate per year, with the capacity to grow significantly in the near future.

Ecovative already operates the largest production plant for mycelium materials in the world, at its base of operations in Green Island, New York. The acquisition of Lambert Spawn Europa makes it possible to supply high-quality raw materials and mycelium strains to a global network of customers and licensees, in addition to the company's own brands. It also reflects an ongoing investment in the mycelium materials supply chain, the use of existing infrastructure whenever possible, and a big step toward full vertical integration that positions Ecovative as the global leader in scaled supply of high quality raw materials for the emerging, fast-growing mycelium technology industry.

About Ecovative:

Ecovative is a materials science company unlocking the natural potential of mycelium with modern technology. Founded in 2007, Ecovative’s mission is to create next generation materials through mycelium biofabrication and to make mycelium materials accessible to everyone. Leveraging its Mycelium Foundry, Ecovative works with partners throughout the textiles, food and packaging industries to grow better materials for everyday needs. To learn more, visit http://www.ecovative.com.

About Lambert:

The L.F. Lambert Spawn Company was established in 1919. Our founder, Louis Lambert was a pioneer in many mushroom spawn manufacturing techniques. Headquartered in Chester County, Pennsylvania, Lambert has been a staple name in the mushroom industry for over a century. Ownership of the company has changed several times during the company's history, with the McIntyre family proudly at the helm since 1991. The same innovative spirit and dedication to quality continue to be the cornerstones of our business principles to this day.

Contacts

Media Contact:

Lacey Davidson

Marketing Director at Ecovative

This email address is being protected from spambots. You need JavaScript enabled to view it.

Major new fundraise positions MycoTechnology to take its mushroom mycelia platform onto the global stage

AURORA, Colo., March 31, 2022 /PRNewswire/ -- MycoTechnology, Inc., the world's leading explorer of mushroom mycelia, has set its sights on achieving global scale and realizing its innovation pipeline after securing a funding injection of $85 million. The recently concluded Series E fundraise represents the Colorado-based company's largest single round of financing since it was established in 2013, bringing total fundraising to-date to more than $200 million.

This new investment will allow MycoTechnology to further capitalize on its proprietary fermentation platform, continuing to impact food and nutrition around the world. The company is now positioned to bring its unique product portfolio to even more consumers globally, with a focus on expanding in Europe, Asia, and the Middle East.

The Series E round was led by a group affiliated with the Oman Investment Authority (OIA), a sovereign wealth fund and first-time investor in the business. Their sights are set on major collaborations around food security and sustainability. In addition to OIA, the Series E funding round attracted several new investors, including Nourish Ventures (Griffith Foods' venture capital group), Rage Capital, Alphacy Investment, and Siddhi Capital. Also contributing were returning investors S2G Ventures, Tyson Ventures, Continental Grain Company, Bunge Ventures, Maple Leaf Foods, Evolution VC Partners, and Gaingels.

Please read the full article here.

Source: CISION PR Newwire, news provided by MycoTechnology, Inc