Canadian agtech company Mycionics has introduced its newest innovation, the Crop Scout, now live at South Mill Champs Mushrooms.

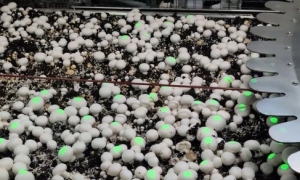

The system scans each mushroom in real time and uses a green light to show harvesters exactly which ones are ready to pick.

By guiding workers to optimal mushrooms, Crop Scout helps farms achieve 4–8% higher yields and improves harvesting efficiency by around 15%. For an industry where labour and timing are critical, this selective approach can significantly cut waste and standardise quality.

The rollout was developed in partnership with South Mill Champs and Christiaens Group BV, marking another step forward in applying robotics and AI to commercial mushroom production.

Mycionics, a Canadian-based pioneer in advanced mushroom harvesting systems, is announcing the launch of its robotic mushroom harvesting and scanning system with South Mill Champs, one of North America’s largest mushroom farms.

A rigorous six-month pilot proved the market’s first economically viable solution to the industry’s pressing labour challenges. Employing a hybrid harvesting approach enabled by the Christiaens Group’s drawer infrastructure, this technology allows humans and robots to work side-by-side on centralized platforms. The method leverages humans for their skill, and robots for their precision and stamina. With two robotic arms, the system harvested 33% of the crop with quality exceeding human harvesting, while also providing real-time crop insights that optimize growing and harvest decisions.

“Having lived through the complexities of robotizing traditional mushroom farms, I am confident in this new hybrid approach,” said Stefan Glibetic, CEO of Mycionics. “Now validated by South Mill Champs’ commitment to this large-scale deployment, it marks a new era for mushroom production.”

Deployment at South Mill Champs will occur in two phases. Phase one, beginning July 2025, will implement Mycionics’ scanning and pointing technologies farm-wide. These are projected to enhance harvesting efficiency by 15% and increase crop yield by 4-8% through guided labour and precision picks. This phase also includes demonstrating Mycionics’ next-gen robotic system, capable of harvesting 75% of the crop through robotic picking, packing, sorting, and grading. Phase two will fully populate the farm with robotics in 2026.

Mycionics is poised to transform the industry beyond North America. Following South Mill Champs’ lead, several farms in Europe have committed to adopting the technology, signalling strong international interest and the broad applicability of Mycionics’ solutions.

For additional information, visit mycionics.com or contact This email address is being protected from spambots. You need JavaScript enabled to view it.

The move comes at a time when the horticulture industry looks to accelerate its automation efforts to benefit Canadian growers.

Vineland Research and Innovation Centre (Vineland) has announced the transfer of its patented robotic mushroom harvesting technology to Mycionics, a Canadian agtech company located in Putnam, Ontario.

The move comes at a time when the horticulture industry looks to accelerate its automation efforts to benefit Canadian growers with Vineland uniquely positioned to contribute, given its innovative technology portfolio.

Under the terms of the agreement, Vineland’s intellectual property will be incorporated into Mycionics patent portfolio as they commercialize their mobile robotic harvesting system.

Please read the full article here.

Source: Greenhouse Canada