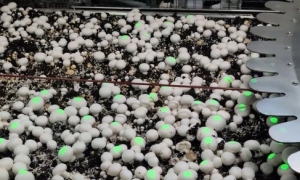

Canadian agtech company Mycionics has introduced its newest innovation, the Crop Scout, now live at South Mill Champs Mushrooms.

The system scans each mushroom in real time and uses a green light to show harvesters exactly which ones are ready to pick.

By guiding workers to optimal mushrooms, Crop Scout helps farms achieve 4–8% higher yields and improves harvesting efficiency by around 15%. For an industry where labour and timing are critical, this selective approach can significantly cut waste and standardise quality.

The rollout was developed in partnership with South Mill Champs and Christiaens Group BV, marking another step forward in applying robotics and AI to commercial mushroom production.

Mycionics, a Canadian-based pioneer in advanced mushroom harvesting systems, is announcing the launch of its robotic mushroom harvesting and scanning system with South Mill Champs, one of North America’s largest mushroom farms.

A rigorous six-month pilot proved the market’s first economically viable solution to the industry’s pressing labour challenges. Employing a hybrid harvesting approach enabled by the Christiaens Group’s drawer infrastructure, this technology allows humans and robots to work side-by-side on centralized platforms. The method leverages humans for their skill, and robots for their precision and stamina. With two robotic arms, the system harvested 33% of the crop with quality exceeding human harvesting, while also providing real-time crop insights that optimize growing and harvest decisions.

“Having lived through the complexities of robotizing traditional mushroom farms, I am confident in this new hybrid approach,” said Stefan Glibetic, CEO of Mycionics. “Now validated by South Mill Champs’ commitment to this large-scale deployment, it marks a new era for mushroom production.”

Deployment at South Mill Champs will occur in two phases. Phase one, beginning July 2025, will implement Mycionics’ scanning and pointing technologies farm-wide. These are projected to enhance harvesting efficiency by 15% and increase crop yield by 4-8% through guided labour and precision picks. This phase also includes demonstrating Mycionics’ next-gen robotic system, capable of harvesting 75% of the crop through robotic picking, packing, sorting, and grading. Phase two will fully populate the farm with robotics in 2026.

Mycionics is poised to transform the industry beyond North America. Following South Mill Champs’ lead, several farms in Europe have committed to adopting the technology, signalling strong international interest and the broad applicability of Mycionics’ solutions.

For additional information, visit mycionics.com or contact This email address is being protected from spambots. You need JavaScript enabled to view it.

An inside look at Christiaens Group in Horst

Recently we, Mushroom Matter, had the pleasure of visiting Christiaens Group in Horst in the Netherlands. During the visit, we were given a tour by Roland van Doremaele, the sales manager who has been with the company for 21 years. What stood out immediately was the strong focus on craftsmanship and the down-to-earth Dutch mentality that characterizes this family business.

A family business with a rich history

Christiaens Group started to make machineries early 70’s, starting as a modest company rooted in strawberry and asparagus farming. The business initially grew around a simple machine for washing, trimming, and manually sorting asparagus. This machine laid the foundation for what would later grow into a global leader in the mushroom and compost industry.

The Christiaens brothers, with their technical expertise and innovative spirit propelled the company forward, especially when they ventured into the mushroom world by developing a filling machine for a mushroom farmer in closeby. With each growing demand for their machines, their reputation further strengthened, leading to exports and collaborations with various suppliers in construction and climate control. This helped Christiaens Group develop a broad expertise, enabling them to realize complete projects.

Growth and development

In the mid-1990s, Christiaens Group B.V. was officially established, with a clear focus on delivering turnkey projects for the mushroom sector.

Initially, the company had operations spread across four locations in Limburg. However, in 2003, they consolidated all activities into a single site in Horst, improving efficiency and collaboration.

An important aspect of their expansion was the creation of separate business units. The Agro division was fully spun off and now operates independently under the name Christiaens Agro Systems. Additionally, other branches within the group specialize in organic solids composting, mycelium cultivation and animal manure, demonstrating the company’s diverse expertise beyond just mushrooms.

Today, Christiaens Group employs around 110 people, with approximately another 150 people working through subcontractors. The headquarters is based in Horst and Christiaens Group has since about 10 years also a production location in China.

Comprehensive solutions and product offerings

Christiaens Group has become a global leader by offering complete turnkey solutions for mushroom farms, composting facilities and mycelium farms. Their services cover every aspect of the process, ensuring that clients receive a fully integrated solution, from design to implementation.

“What makes Christiaens Group truly unique is that all our solutions are designed and produced entirely in-house. This level of control allows us to ensure the highest quality from start to finish. While we’re known for handling large-scale projects, we’re also fully equipped to take on smaller projects and provide by example individual machines, hydraulic lorries or airhandling systems, making our expertise accessible to a wide range of clients.” — says Roland.

Their key solutions include:

- Engineering: The setup and engineering of complete projects in the mushroom and waste industries.

- Construction: Expertise in constructing mushroom farms and composting plants, ensuring durability and efficiency.

- Technical Installation: Installation of air handling systems, technical installations for climate control, and odor management solutions.

- Controls: Advanced control technology for managing all processes in mushroom cultivation and compost production.

- Machines: Design and production of high-quality machinery for compost production and mushroom cultivation

Christiaens Group's product portfolio includes:

- Composting systems:

- Phase 1 bunkers

- Phase 1 tunnels

- Phase 2/3 tunnels

- Growing Systems:

- Dutch shelving system

- Tilting system

- Drawer system

- Organic Waste Composting:

- Composting systems

- Odour management technologies

•

- Mycelium Cultivation:

- Mycelium growing systems

- Substrate preparation

- Product handling systems

Innovation and sustainability as core values

Innovation and sustainability are key at Christiaens Group. They understand that it is important to produce high-quality mushrooms and compost while using as few natural resources as possible. Therefore, they continuously work on new concepts that improve harvesting efficiency, energy efficiency, and safety.

A good example of their commitment to sustainability is the investment in 20,000 m2 solar panels on their premises, allowing them to operate completely energy neutral and with use of heatpumps without gas for heating the building. This not only contributes to lower energy costs but also to a cleaner environment.

Christiaens Group is focused on technological innovation in mushroom harvesting. Due to global labor shortages, they have partnered with a specialist in robotics, to develop an advanced robotic solution for harvesting mushrooms in their Drawer System. This collaboration came about with great interest during the Dutch Mushroom Days in spring 2023, the largest event in the mushroom sector.

Christiaens Group collaborated with Heereco, a pioneer in organic mushroom cultivation in the Netherlands, to implement one of the first fully automated solutions for mushroom harvesting in the fresh market. This system integrates Christiaens' future-proof Drawer System with an advanced robotic technology. The result is a revolutionary automated harvesting process that significantly increases productivity and reduces labor dependency while enhancing the quality of the mushrooms. The system also includes advanced automation in the packaging process, ensuring consistency and efficiency from harvest to shipment.

Mycelium products

Christiaens Group is also the technical partner of Mycelium Materials Europe (MME), a Dutch start-up founded in 2018. MME is active in the bio-based materials and circular economy, producing sustainable mycelium materials based on mushroom technology. Mycelium, the underground network of fungi, is grown in MME’s own mushroom farm using organic waste such as sawdust from sawmills. These mycelium materials are biodegradable and are used by designers, the construction industry, and the fashion industry.

Christiaens Group’s partnership with MME highlights their commitment to sustainability and innovation, extending their expertise beyond traditional mushroom and compost production into emerging sectors focused on eco-friendly materials.

A Company with a future

During our visit to Christiaens Group, it quickly became clear that this is more than just a business—it’s a family rooted in tradition, with a constant eye on the future. The company’s long-term success is built on ongoing investments in innovation, sustainability, and global growth. This approach allows them to maintain their leadership in the mushroom, compost and mycelium industry while staying grounded in the values that have defined them for decades.

"Many of our team members have been with us for decades—it’s not uncommon to celebrate work anniversaries of over 25 years.” says Roland van Doremaele. "It’s this passion, combined with the company’s welcoming culture, that creates such strong employee loyalty. “

With a down-to-earth attitude, a commitment to quality, and a focus on both people and progress, Christiaens Group is more than prepared to take on the challenges of the future.

Walkro study group visits EuroMycel

Quite a while ago Walkro organized a study trip to France and asked EuroMycel to help in this. Unfortunately due to the Covid restrictions the trip had to be delayed until further notice. Then finally the journey took off on September 22nd!

The study trip lasted from September 22nd to September 25th and the program was fully packed with interesting company visits, presentations and amongst learning from each other, a lot of pleasure together. Walkro, the initiator of this study trip, gathered a number of sponsors to get the program well organized.

Sponsors were: Christiaens Group, MC Substradd, Legro, Gicom, Sylvan and Walkro.

On Wednesday September 22nd the group that consisted of Dutch growers, sponsors and organizers, travelled to the Bonduelle facilities in Estrees-Mons by bus. They received a tour in the fields of the Bonduelle yellow beans and visited their factory.

On Thursday morning a visit to the Bonduelle Compost & Yield in La Tourte was scheduled. This was quite interesting especially for Walkro, because here they saw how colleagues work with the same product.

In the afternoon the study group was invited by EuroMycel on their premises. The tour facilitator was Frédéric Mathieu, operational director EuroMycel, and Yves & Rémy of the lab, they are very important for the Operational team. Also Jeroen Dunant, our sales manager, who is our eyes and ears in the field and helps us expand with new customers and in new countries. The tour was received with a lot of enthusiasm! The group was pleasantly surprised and impressed by Euromycel's way of working, given the fact that they are a relatively new player in the industry. Also sharing knowledge amongst colleagues who work with the same products, was well respected.

Photo to the right:

Photo to the right:

From left to right below:

Frederic Mathieu, Jeroen Dunant, Eddy Alkemade

From left to right above:

Yves Moriamez, Evert Jan Mink, Remy Maufrand

EuroMycel took the whole group on an eventful evening program, which took place in the Caves Angelliaume. Cave Painctes in Chinon. They were welcomed by gentlemen holding the title “Confrérie des Entonneurs Rabalaisiens”. In English “Brotherhood of Rabalaisien Entonneurs”.

Dinner was accompanied by a wine arrangement and theatre performance. There was also a surprise for several people who got acknowledged for some special activities in the Mushroom Industry.

Interesting cultural and historical fact to mention is that the location of EuroMycel, L`Ile Bouchard in the Loire region, is well known for the combination of wine and mushrooms. Hence the set-up of the evening program. The wine was produced on the land and the mushrooms in the caves, the name Champignon de Paris stems from this fact.

On Friday 24th, the group left for Saumur and Paris to spend some time in the ‘City of light’!

The study group packed their luggage for their journey back home. And not only with what they came with, but also with many new and interesting experiences!

The whole Walkro group at the wine tasting facility

at Caves Angelliaume. Cave Painctes in Chinon”