Optimizing Mushroom Harvesting: Advanced Automation for the Fresh Market

Global mushroom growers face rising labor costs and a shortage of skilled pickers. GTL Europe provides a high-tech solution to these industrial challenges. We combine the Automatic Picking Lorry with the Mycosense Spotlight System.

This integration transforms manual harvesting into a professional and data-driven operation.

Intelligent Guidance: The Mycosense Spotlight System

The Spotlight System acts as the brain of the harvesting process. It scans the growing shelves in real-time. Centralized software then projects light points directly onto the mushrooms that require picking.

The lorry uses this data to automatically accelerate or decelerate. This cruise-control function adjusts the speed based on mushroom density. It ensures the picker stays in the most productive zone without manual intervention. The system provides accurate instructions and detailed performance data for the grower.

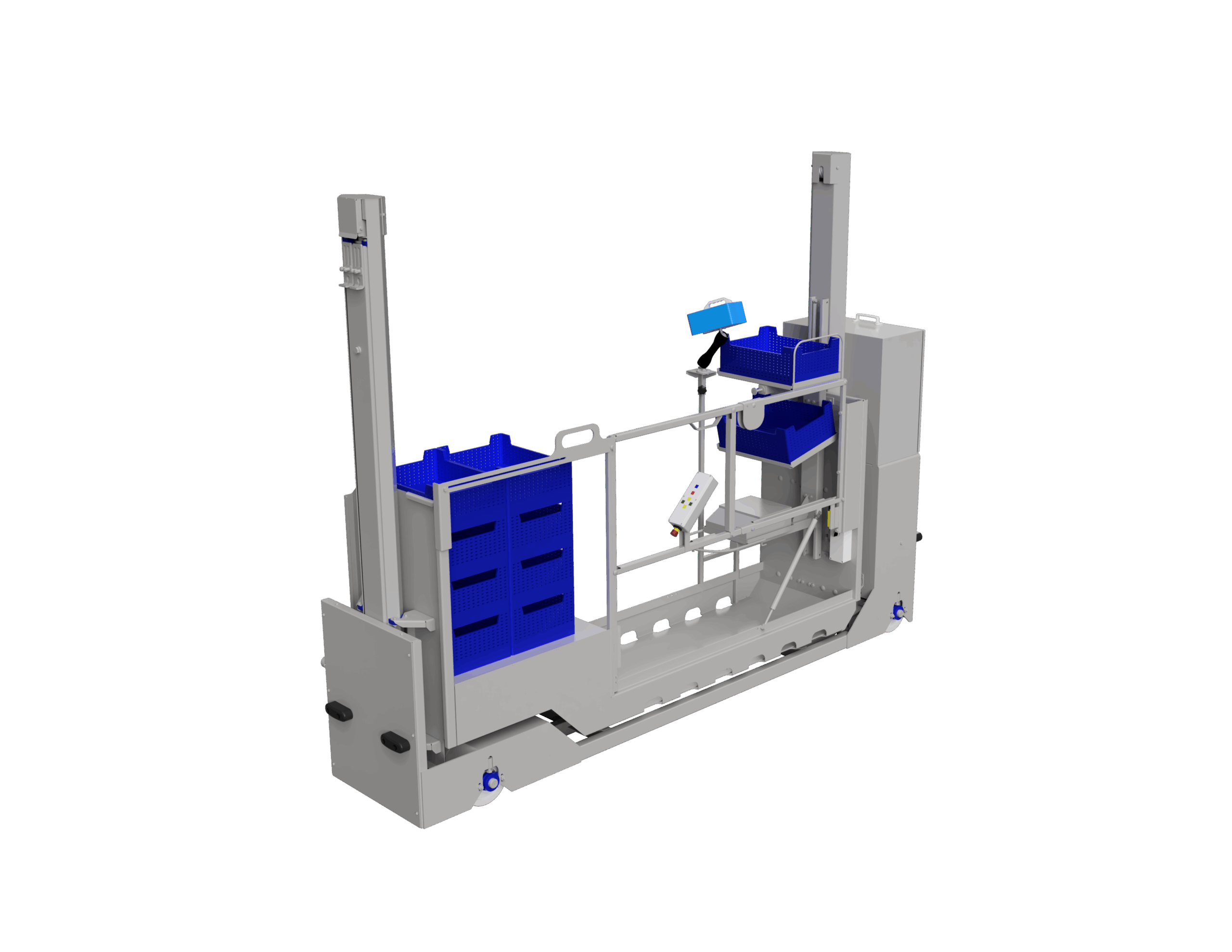

Engineering Excellence: The Automatic Picking Lorry

The GTL Automatic Picking Lorry is engineered for durability and safety. The machine features a robust aluminum frame and a stainless steel work platform. An integrated electric lifting system brings the picker to the ideal working height for every shelf.

A critical component is the integrated harvesting conveyor. It gently transports mushrooms away immediately after they are harvested. This eliminates the need for manual handling of crates or boxes. The machine also includes integrated LED lighting and is prepared for connection to a watering boom.

Intelligence through the Mycosense Spotlight System

The Spotlight System acts as the brain of the harvesting operation. It scans the growing shelves in real-time. Centralized software then projects light points directly onto the mushrooms that require picking.

This guidance ensures that every picker follows the exact instructions of the grower. The system provides detailed performance data and real-time monitoring. This allows for smarter decisions based on reliable facts instead of estimates.

Measurable Efficiency and Yield Increases

Field tests provide clear evidence of the system performance. Growers can expect significant improvements in both output and quality. Key results include:

- A higher yield of +2 to +6% during the first and second flushes.

- A picking speed increase between 10 and 27%.

- Training time for new staff reduced from months to just a few days.

- A significant reduction in picker fatigue and the need for direct supervision.

- Consistent punnet sizes and better-organized growing beds.

- Reliable data as a foundation for smarter decisions.

Implementation in Existing Facilities

GTL Europe designs these systems to be compatible with existing mushroom farms. The transition to automated assistance is straightforward. To implement this technology in an existing facility, the following elements are required:

Shelf Compatibility: The system is designed to work with standard professional shelving systems in modern growing rooms.

Power Supply: Access to a reliable electrical connection is necessary for the charging and operation of the lifting systems.

Software Integration: The centralized control software must be connected to the farm network to manage picking instructions.

Floor or Rail Setup: The lorries can be configured for either floor-running or rail-running setups depending on the current infrastructure.

Engineering Excellence from Venlo

At GTL Europe, we manage the entire production process in-house. Our engineering team in Venlo, The Netherlands, ensures that every component meets the highest standards. We offer full after-sales support and service to ensure long-term reliability. By choosing GTL Europe, you invest in a turnkey solution that brings your facility into the future of mushroom harvesting.